Polymermedics Chooses Wittmann Machines for its New Class 7 Cleanroom

|

Getting your Trinity Audio player ready...

|

St Austell-based injection moulder, Polymermedics, has just completed a new and bespoke Class 7 cleanroom, equipped with four new Wittmann SmartPower injection moulding machines with various locking forces and with automation and ancillary equipment.

The new investment confirms the status of Polymermedics as a premier supplier to the international medical and healthcare markets. The company was founded in 1979 as a medical injection moulder for West Pharmaceutical. Now under private ownership, the company will exhibit its current capabilities and manufacturing services at the Med Tech Innovation Show, NEC Birmingham, June 5-6th 2024.

Polymermedics currently employs a total of seventy-five staff – including four apprentices, three process setters and one engineering, and 5 toolmakers. The facility is home to a total of 35 injection moulding machines with robotics and automation, ranging from 5 to 350 tonnes – running 24/7 through the year.

Neil Skyba says that “we are delighted to open our new cleanroom for customers in medical and healthcare. From the beginning our entire production culture has been geared to the exacting demands of the medical business. The last twelve months have seen us developing new production capabilities in a very active manner. This new Class 7 cleanroom – equipped with Wittmann machines and technology – will be the jewel in our crown going forward.”

Adrian Walters, Wittmann Sales Manager, says that compact, ergonomic machine design, ultra-low energy demands, and the widest possible platen area are the three machine design factors helping him to win this and other orders in the current climate. The Wittmann Group’s upcoming Competence Days, June 19-20 in Vienna, Austria are expected to demonstrate these qualities further – including cleanroom-equipped machines and micro moulding technology made bespoke for medical.

The successful Class 7 cleanroom build at Polymermedics – carried out by KiiK – was critical to the project. Keanu Churchyard, Managing Director, says that “we have extensive experience in the medical field and after several site visits we were ready to tackle the unique demands of the legacy space – a high triangular roof that required a unique design and solution for the air handling system. It was a pleasure to work with Neil, Lee and the team at Polymermedics, and their responsiveness and collaborative nature helped to ensure that the project was completed On Time and In Full.”

With over 45 years of medical manufacturing behind it, Polymermedics is confident that it runs the very highest standards of medical manufacturing process validation for injection moulding in Europe. The business is also accredited to the Silver EcoVadis environmental standard. Neil Skyba says that “many international medical businesses now set very expensive thresholds in terms of the money that must be spent on process validation for all their contracted manufacturing. Fortunately our business has already accumulated all the major relevant standards – and we are therefore ready straightaway for the largest OEM customers as well as the solo designer and medical inventor.”

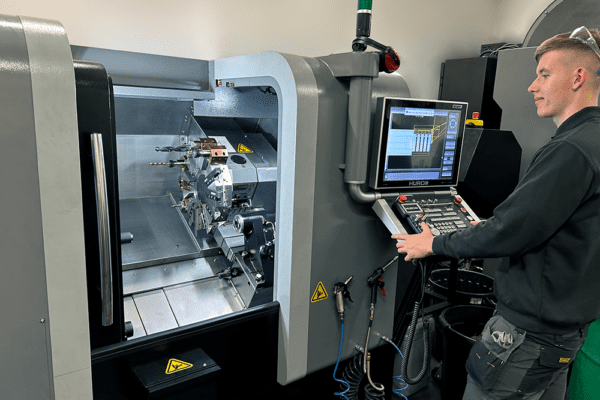

Polymermedics has also lately been investing in a fully equipped precision engineering facility and a state-of-the-art metrology department. Neil Skyba notes that “we are happy to regularly push the boundaries and possibilities in medical manufacturing – commissioning a 128 cavity mould tool this week or trialling water soluble catheters in PVOH materials. We are very much looking forward to showing our full and current strength at next month’s Med Tech Expo – and we hope to see you there.”

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275777

Website

Email