WITTMANN Harnessing Direct Current for Injection Moulding

|

Getting your Trinity Audio player ready...

|

Photovoltaic systems have become increasingly common on the rooftops of industrial companies. Rising energy costs, purchasing restrictions, and grid instability in certain regions make partial independence from the electricity market highly attractive. Additionally, adopting renewable energy supports businesses in achieving their sustainability targets. However, there remains significant untapped potential to maximise the efficient use of renewable energy. WITTMANN, in collaboration with its partner inesco AG, is helping injection moulding companies unlock this potential. The solution lies in harnessing direct current (DC) as a direct energy source for operations.

It is 2022, and the K trade fair in Germany is underway. Visitors to the WITTMANN booth in Hall 12 are witnessing a groundbreaking innovation. An injection moulding production cell, producing electronic parts from flame-retardant polyamide, is equipped with striking solar panels. This conceptual study, presented by WITTMANN in collaboration with a customer, demonstrates the future of sustainable manufacturing.

With the necessary infrastructure in place, the injection moulding machine and robot are powered directly by solar energy through a DC link. This revolutionary development has led the two partner companies to jointly file a patent, marking a significant step forward in energy-efficient production technology.

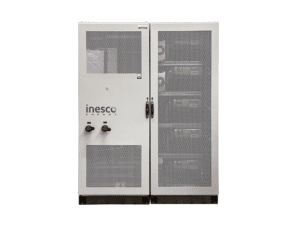

Fast-forward to Fakuma 2023 and WITTMANN once again showcased a production cell powered directly by solar energy via direct current (DC). This time, the concept had evolved into a production-ready solution complete with solar power storage. To industrialise and market DC injection moulding technology, WITTMANN has partnered with inesco AG, a company that has spent over a decade researching how renewable energy can be effectively utilised and efficiently stored on a large scale.

The presentation at Fakuma 2023 marked a turning point, sparking significant interest from the injection moulding industry in the direct use of solar power through DC grids. In response, WITTMANN and inesco AG are now evaluating numerous inquiries for specific projects, with the first DC-capable injection moulding machines already sold.

WITTMANN has emerged as a pioneer in DC technology for the injection moulding sector, becoming the first supplier to deliver machines and production cells capable of using solar energy sourced directly from a DC grid.

Focus on the Security of the Supply

Like other forms of renewable energy, such as wind farms and biogas plants, solar power is generated as direct current (DC). However, national power grids operate using alternating current (AC). Before renewable energy can be utilised, it must first be converted into AC for transportation and distribution—and, in many cases, transformed back into DC at the point of consumption, as numerous industrial and everyday applications rely on DC.

The converters used in these processes are often frequency inverters, which enable variable-speed control of electric motors—devices that account for 70% of industrial power consumption. Other examples of DC consumers include computers, televisions, LED lamps, and electric vehicles.

Within both industrial production and daily life, DC is continually being converted to AC and vice versa. Each transformation results in an energy loss of approximately 2 to 4%, reducing overall energy efficiency. This challenge led to the concept of decentralised DC networks, known as DC microgrids, which allow direct current to be utilised without first being converted into AC, thereby improving energy efficiency.

In addition to energy savings and the resulting reduction in carbon footprint, there are several other compelling reasons to explore the potential of DC technology. Chief among these is the security of supply. Rising electricity demand, driven by factors such as the increasing use of electric vehicles, heat pumps, and the growing electrification of industrial production, is placing significant strain on existing power grids—many of which are not expanding at the same pace as these developments.

This challenge is further intensified by the rapid increase in feed-in solar power, which adds additional pressure to grids and contributes to their instability. Experts warn that even countries with reliable electricity networks, such as Germany and Austria, may face grid failures and restrictions on consumption in the future. Direct current (DC) grids could therefore become a vital solution for enhancing supply security and achieving climate neutrality.

One key advantage is that DC can be easily stored in batteries, offering an efficient method for managing costly power peaks. Another benefit lies in resource efficiency when expanding power grids. Modern three-wire DC grids require significantly less copper conductor material than traditional five-wire AC grids, as well as fewer electronic components, as rectifiers are no longer needed in the equipment.

Solar Storage Batteries Keep Output Constant

What does the direct use of solar power in injection moulding operations look like in practice? WITTMANN’s solution combines three key components: a WITTMANN injection moulding machine or production cell modified for DC technology, inesco’s DC network “DConnect,” and the sodistore max storage battery, which utilises natrium salt. Designed specifically for sustainable industrial use, the salt battery offers an environmentally conscious energy storage solution.

The DConnect system serves as the backbone of the DC power supply during operation. It is a self-regulating DC microgrid that allows seamless integration and interconnection of both DC producers and consumers. Notably, DConnect operates without an external controller and does not rely on an internet connection, ensuring the system remains secure and protected against cyber threats.

The sodistore max storage battery plays a critical role in maintaining constant voltage, even when multiple consumers are connected, or power supply levels fluctuate. Inesco’s solar power storage batteries are available in various sizes, offering storage capacities of up to 500 kWh to meet the diverse needs of industrial operations.

The salt batteries deliver the same energy density and volume as conventional lithium-ion batteries but offer the advantage of significantly higher charging and discharging rates. Sodium-ion batteries are not only safer but also far more environmentally friendly than traditional lithium batteries. They are free from hazardous materials, fully recyclable at the end of their service life, and do not require air conditioning. This makes them suitable for operation indoors at temperatures of up to 55°C and outdoors in extremely low temperatures as cold as -20°C.

For integration into the DConnect microgrid, WITTMANN is initially offering its EcoPower series of injection moulding machines, along with the DC-compatible models of its WX linear robots. Development is ongoing to expand the range of machines and peripheral devices compatible with DC grids. For instance, at its Competence Days Event in the summer of 2024, WITTMANN introduced DC temperature-control devices, marking another step forward in sustainable manufacturing solutions.

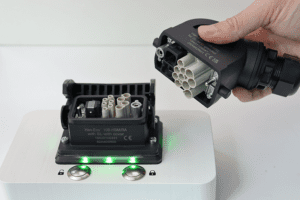

To ensure safe operation, the connection technology also required adaptation. For this purpose, the HARTING Technology Group developed a prototype for an electrically lockable connector specifically for this application. This connector protects both the system and employees from accidental disconnection, which could otherwise result in electric arcs. An integrated signal indicator further enhances safety by showing at all times whether voltage is present at the connector.

The all-electric EcoPower machines, which are equipped with highly dynamic servomotors for driving the main movements, are ideal for use in a DC grid. They feature a patented kinetic energy recovery system (KERS) that converts kinetic energy into electrical energy during braking. In a conventional AC set-up, this recovered energy can only be used inside the machine, e.g. to heat the barrel. When integrated into a DC grid, however, it can also be fed back into the DC grid for use by other consumers or for storage within the battery. The DC model of the WITTMANN robot, which is supplied directly via the DC link of the EcoPower machine, also feeds excess energy back into the DC link when braking.

The production cell presented at the latest trade shows comprised an EcoPower B8X 180/750+ injection moulding machine with an installed salt storage capacity of 45 kWh. It operated non-stop over the entire eight-hour trade fair day without the need to switch to the AC grid at any time.

Cutting Energy Consumption by up to 15 Percent

Initial practical tests show that the reduction in conversion losses alone shaves up to 15 % off the power demand of a production cell supplied directly with DC. Any decision-making about whether or not to create a DC grid should not focus on whether one technology is superior to the other. Instead, DC grids will be set up alongside AC grids in more and more areas. For example, if the battery storage becomes exhausted at some stage on an overcast day with little sunlight, the system developed jointly by WITTMANN and inesco will automatically switch to AC. The switch will not be noticeable in production; the machine will be fed with a continuous, steady supply of power.

In the long term, too, it is likely that AC and DC grids will exist in parallel. This will allow decisions to be made on a case-by-case basis as to which power supply offers the greatest overall efficiency.

Technical Challenges Solved

How quickly will DC become established in the injection moulding industry? There is no easy answer to this question, as many factors are involved. The first task is to publicise the possibilities and advantages of DC technology more widely, to find reference applications and to share experiences more intensively across industries.

The technical challenges, at any rate, have been solved. Industrial-grade solutions, components and protection mechanisms are available. However, what is needed more than that is a change of awareness. Factory planners, architects, electricians and energy consultants need to be made aware of DC technology so that it can be considered from the outset when new investments are being made.

Politicians and industry associations also need to play their part. Having recognised the key importance of renewable energies for the energy transition, the German government launched its first joint research project back in 2016. This led to the emergence of the Open DC Alliance (ODCA) working group within the German Electrical and Electronic Manufacturers’ Association (ZVEI) in 2022. Many well-known global companies have joined the ODCA, including inesco.

ROI Possible in Just a Few Seconds

Although existing photovoltaic systems can be converted to direct DC power, replacing all inverters with DC-DC converters would be a massive undertaking. The fastest return on investment when setting up and operating a DC microgrid is made at the time a new DC-coupled photovoltaic system is being installed. That way, power and load management can be optimally designed from the outset. It is also advisable for the DC network to integrate not only the injection moulding production cells but also the peripherals and parts of the infrastructure, such as the compressed air supply, lighting and air conditioning.

What most affects the ROI, though, is the stability of the power supply on location. Where power supplies are frequently interrupted or the amount of supplied power is restricted, a DC microgrid with DC-coupled battery storage pays for itself particularly quickly. In the case of very critical components, the payback on a DC power supply can be made in a matter of seconds when a blackout occurs.

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275 777

Website

Email