WITTMANN BATTENFELD present VPower COMBIMOULD at K 2019

At K Show 2019 in Düsseldorf, Wittmann will present for the first time the COMBIMOULD version of its new VPower vertical machine series, under the motto “Enjoy innovation.”

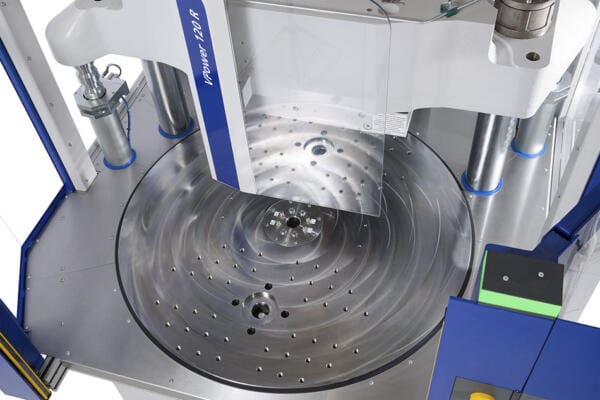

The new vertical machine model designed according to the PowerSeries concept was successfully launched by WITTMANN BATTENFELD at the beginning of 2019 in the sizes of 120 and 160 tons. Now this machine series is also available in the sizes of 220 and 300 tons with rotary table diameters of 1300, 1600 and 2000 mm.

In addition to extending the machine series upwards, the company has worked on the development of the multi-component version of the VPower. The latter will be presented to a broad public for the first time at the K 2019. From this year’s autumn onwards, all VPower machines will now also be available on the market in the COMBIMOULD version. The drive unit of the VPower provides the basic prerequisites for operation with two aggregates. In the standard configuration, the second hydraulic system is used for ejection during the injection moulding cycle. But in multi-component applications, it powers the second injection unit, so that both injection units can always carry out injection and metering simultaneously. If the machine has been prepared for 2-component operation, it can either be ordered as a 2-component injection moulding machine ex works, or be retrofitted with a second plasticising unit later.

The VPower distinguishes itself from its predecessor models above all by its innovative 2-tie-bar rotary table concept, which provides optimal accessibility thanks to dispensing with the middle tie-bar. The tie-bar-less rotation centre leaves ample space under the rotary table for cooling water, hydraulic oil, compressed air and power supply connections. The generously dimensioned rotary tables are combined with a 2-tie-bar portal clamping unit equipped with two travel cylinders on the outside for fast opening and closing. The rotary tables are available with servo-electric drives for short rotation times and highly accurate positioning and are laid out for both oscillating 2-station operation and rotary 2-, 3- or 4-station operation.

The UNIFORCE compensation plate system between the horizontal beams of the clamping unit and the mould clamping area ensures even and gentle force transmission to the mould.

The injection unit can also be converted at a later date from vertical to horizontal or vice versa.

The machine’s open design makes it particularly well suited for the integration of automation systems with insert feeding and finished parts removal.

At the K 2019, WITTMANN BATTENFELD will demonstrate the functionality of the VPower COMBIMOULD using a VPower 120/130H/210V. With this machine, a plug made of PA and TPE for the automotive industry will be manufactured with a 2+2-cavity mould. The complete automation system for the machine is designed by WITTMANN BATTENFELD Deutschland in Nuremberg. In this application, a Scara robot and a WX142 linear robot from WITTMANN are used, which insert the wrap pins, transfer the preforms, then remove and deposit the finished parts.

WITTMANN BATTENFELD at K 2019: hall 15, stand C06.

Wittmann Battenfeld

+44 (0)1933 275777

Website

Email