WITTMANN BATTENFELD Showcase Energy-Efficient Injection Moulding Technology at Fakuma 2023

From 17 to 21 October, WITTMANN BATTENFELD will present to visitors ultra-modern injection moulding technology with minimal energy consumption at the Fakuma in Hall B1, booth No. 1204. One main focus of this presentation will lie on the new EcoPower B8X, which stands out, particularly by its latest energy efficiency and precision improvements.

With the development of the PowerSeries, WITTMANN BATTENFELD has created a machine series characterised primarily by high performance and repeatability combined with low energy consumption. This applies in particular to the all-electric machines from the EcoPower and MicroPower series and the servo-hydraulic SmartPower models. Thanks to the continuous optimisation of these machines’ performance capacity and cost efficiency, WITTMANN BATTENFELD now offers a range of machine models which play a pioneering role on the market in terms of energy efficiency.

To demonstrate to visitors the economic and technical advantages of the energy efficiency offered by the machines and appliances from WITTMANN BATTENFELD, an energy efficiency path comprising a total of 8 stations will be created at the company’s booth. The machines exhibited along the energy efficiency path range from an EcoPower B8X, a MacroPower and a SmartPrimus machine all the way to the conceptual machine model EcoPower DC, which draws its power supply solely from a battery as DC voltage source.

A trade fair highlight: even greater energy efficiency with the new EcoPower B8X

At the Fakuma 2023, WITTMANN BATTENFELD will present for the first time its new EcoPower B8X, which offers several advantages in addition to a further reduction of its energy consumption compared to its predecessor version. Particularly noteworthy here are above all the innovations in the areas of the injection unit, the toggle lever and the machine’s dynamism. For instance, the new injection unit is pivotable and oil-lubricated instead of grease-lubricated, whereby the mechanical resistance is reduced, thus improving the machine’s dynamism. Combined with a range of additional injection unit sizes, this positively affects the energy balance. The design of the toggle lever has been optimised for dynamism and service life. The faster injection units in combination with the highly dynamic toggle lever enable extremely short cycle times.

The B8X control system comes with several system components developed in-house. These enable a higher internal clock frequency, consequently shorter response times to sensor signals and thus a higher reproducibility of parts, with the comfortable operation and familiar visualisation remaining unchanged.

The new EcoPower B8X will be available to the European market in clamping force sizes from 550 to 1800 kN from the Fakuma 2023 onwards.

The functionality of the new EcoPower B8X will be demonstrated on an EcoPower 110/350 B8X in combination with the new WITTMANN sprue picker model WX90, designed as an Insider cell with an integrated parts chute and an S-Max screenless granulator, plus a WFC120 flow controller. With this production cell, a bracket for a climbing net will be produced using an 8-cavity mould supplied by Lechner, Austria. The sprue will be removed and transported directly into the granulator integrated in the machine by the WX90, which is also integrated in the B8X control system. There it is ground and subsequently returned to the process.

A world premiere: EcoPower DC – direct current as energy source in injection moulding technology

Solar cells on corporate roofs offer companies the possibility to generate their own electricity and thus not only to save costs but simultaneously protect the environment. WITTMANN BATTENFELD has investigated the question of how the direct current generated by solar cells can be used effectively for running injection moulding equipment directly without first passing through inverters. The conceptual study about this subject was presented for the first time at the K 2022. Meanwhile, WITTMANN BATTENFELD has taken further development steps to advance this type of technology since the use of direct current to operate an injection moulding machine has a number of advantages. Firstly, the energy costs can be kept low by the direct use of solar power, and secondly, direct current can easily be stored in conventional batteries as an ideal solution to cover expensive current peaks and to increase supply security. Moreover, using direct current technology leads to increased energy efficiency, which contributes to reducing CO2 emissions and preserving resources.

At the Fakuma, this technology will be demonstrated on an EcoPower 180/750+ B8X. With a single-cavity mould from the Austrian company Kunststofftechnik Grabher GmbH, a drainage body will be manufactured from polypropylene. The part will be removed by a modified WX142 robot in DC version from WITTMANN, which draws its power supply directly from the interim DC voltage circuit of the EcoPower and also returns any surplus energy to the interim circuit whenever the axes are delayed. To enable a live presentation of the DC technology to the visitors, the machine remains disconnected from the mains network of the exhibition hall during the fair and is powered independently via a solar power storage battery consisting of ultra-modern, ecological salt battery technology supplied by Innovenergy. The battery has a total capacity of over 45 kWh, which is more than sufficient for continuous machine operation throughout an entire 8-hour trade fair day.

SmartPrimus combined with high-tech automation equipment in a digital network

WITTMANN BATTENFELD will prove its expertise in digitization and automation at the Fakuma by producing a spirit level on a machine of the SmartPrimus series with the new B8X control system. The servo-hydraulic SmartPrimus, previously known as SmartPlus, stands out by a high degree of cost and energy efficiency, and excellent repeatability. By using proven technologies combined with carefully selected options, offering an excellent price/performance ratio for these machines has become possible.

On a SmartPrimus 90/350 equipped with the CMS Lite conditioning monitoring system and an automation cell designed and manufactured by WITTMANN BATTENFELD Deutschland, a spirit level made of ABS is produced with a 1+1-cavity mould supplied by SOLA, Austria. As a first production step, the top and bottom parts of the spirit level housing are injection moulded. The top part is then deposited and printed at a laser station. Simultaneously, the bottom part placed on a tray is fitted with vials from SOLA. Next, a pre-set force presses the top part onto the bottom. The finished parts are then transported to a testing station, where a vision system checks the positioning of the vials. After quality inspection, the finished spirit levels are removed and deposited on a conveyor belt by a WX138 robot from WITTMANN.

Liquid silicone processing with MicroPower LIM

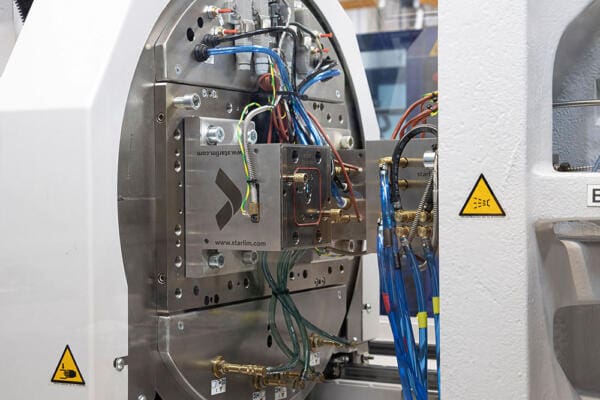

The MicroPower, a machine laid out for injection-moulding micro parts, is also extremely energy efficient due to its design, as are the auxiliaries specially tailored to match this machine. At the Fakuma, WITTMANN BATTENFELD will demonstrate its liquid silicone processing expertise on a MicroPower 15/10H/10H Combimould. The LSR application to be presented is the production of a membrane for an upmarket micro loudspeaker made of thermoplastic and liquid silicone, using only a single-cavity mould supplied by Starlim Spritzguss GmbH, Austria. The choice of a single-cavity mould demonstrates the high precision of the mould in combination with the machine, which is specially designed for producing micro parts.

It is often necessary to build costly multi-cavity moulds already at the prototyping stage to reach the minimum throughput of the machine. The MicroPower has a 2-step screw-and-plunger thermoplastic aggregate and a 2-step screw-and-plunger LSR aggregate. The LSR metering pump supplied by EMT Dosiertechnik, Germany, is a 1-litre cartridge system developed for extremely small metering volumes. Smooth, continuous emptying of the cartridges ensures the highest precision together with consistent quality. Another advantage is the blending section is reduced to a minimum, with the special benefit of rapid cleaning and minimal material loss with every material changeover.

Saving resources with light-weight technology

In addition to its machinery and equipment exhibits, WITTMANN BATTENFELD will also present its latest developments in Airmould internal gas pressure technology. The items to be showcased are the new Airmould 4.0 pressure control module and the new manual operating unit for this technology. At an Airmould / Cellmould workstation, expert engineers from the company will be on-site to advise visitors concerning using Airmould technology and Cellmould structured foam technology. Both of these technologies enable significant reductions of material input in the production of plastic parts, with a simultaneous positive effect on part weights and production costs.

Energy measurement

On every machine at the booth, an energy measurement will be carried out using the IMAGOxt software. IMAGOxt is a proprietary development from WITTMANN Digital Srl. The software provides scalable display and visualization of the energy consumption of the machines and equipment connected. The program also calculates directly the CO2 consumption and energy savings already realized. All values calculated can be documented in reports and thus remain available for long-term analyses. This program is available as a web application either as an optional extension to the TEMI+ MES program from WITTMANN or as a stand-alone program. This will be of particular interest as soon as there are funding options for new energy-saving investments in place in EU countries. The IMAGOxt program is certified according to DIN ISO 50 001. Consequently, the investment costs for this product are eligible for funding contributions in Germany.

WITTMANN BATTENFELD offers its customers a selection of energy consulting packages tailored to the market. These range from mere energy consumption analyses according to Euromap 60.1 and 60.2 and an extended analysis, including the auxiliary appliances, to optimising an entire process based on such analyses.

At a TEMI+ workstation specially created for this purpose at the WITTMANN Group’s Fakuma fair booth, visitors to the fair will have an opportunity to gather detailed information about the TEMI+ MES program and the IMAGOxt energy management software, as well as to receive advice concerning energy management improvements and resulting cost cuts for their own company.

Silicone processing machine at external booth

At the booth No. 4310 of Kracht, Germany in hall A4, liquid silicone processing will be demonstrated on an EcoPower 110/350 B8X. The machine is equipped with an LSR metering pump from Kracht. Using an 8-cavity mould supplied by EMDE MouldTec, Germany, a baby care pacifier will be produced from LSR.

For more news from WITTMANN Group, click here.