WIBA UK Customers Party at 10th Anniversary in Vienna

Wittmann Battenfeld (WIBA) UK Managing Director Barry Hill says that the 10th anniversary party to celebrate Wittmann’s purchase of Battenfeld, June 12-14 was a landmark occasion, confirming the company’s growing contributions to the world of injection moulding.

‘It gave us great pride to be a part of this anniversary celebration,’ said Hill. ‘Not only have we seen some leading-edge moulding technology but we have also had the chance to catch up with the worldwide Wittmann Group network. The event also gave WIBA UK the opportunity to field enquiries and take customer orders.’

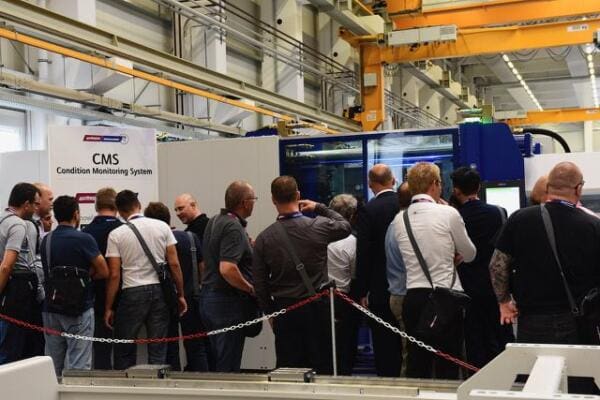

A party of over 50 UK and Irish customers joined WIBA UK staff in order to join the celebrations in central Vienna and to witness the ongoing expansion of the Wittmann Battenfeld works in Kottingbrunn

WIBA UK’s guests had the opportunity to experience the company’s expertise first-hand with 14 machines from the PowerSeries demonstrating interesting new processes and applications. The exhibition was rounded off with numerous innovations from the range of Wittmann robots and peripherals.

The integration of Battenfeld Kunststofftechnik into the Wittmann Group 10 years ago was, among other things, the starting point for the revision and new development of the company’s entire range of machines. A machine portfolio was developed under the brand name PowerSeries, which is now the market leader in terms of energy efficiency.

June 13 and 14 saw the Wittmann Group introducing new machines to the market, including the prototype of the new VPower, the company’s vertical machine in the latest PowerSeries design. A VPower 160/750 with a rotary table 1600 mm in diameter and with a servo-electric drive was on display.

This vertical moulding machine has a substantially reduced footprint, its low, ergonomic working height is very convenient for users, and its generously dimensioned servo-electric rotary table ensures short rotary times. Thanks to its open design, the machine is ideally suited for the integration of automation systems with insert feeding and finished parts removal functions.

Another innovation presented at the anniversary celebrations was the 500-ton version of the high-speed EcoPower Xpress, an EcoPower Xpress 500/3300+, on which a 2.8 litre bucket was manufactured with a 4-cavity mould supplied by Abate, Italy, using IML technology from WITTMANN.

Visitors at the event also got an opportunity to witness the largest machine currently manufactured in Kottingbrunn, a MacroPower 2000/12800H/350L COMBIMOULD. This machine is the 2-component version of the largest machine model in the MacroPower series. It is equipped with a robot from the new WX series from WITTMANN, a WX173.

The full scope of WITTMANN 4.0 integration was also demonstrated at the Kottingbrunn factory using an EcoPower 90/350, in whose UNILOG B8 control system the robot and all peripherals connected to the machine have been integrated.

Wittmann Battenfeld

+44 (0) 1933 275777

Website

Email