What is Plasma Cleaning?

In this blog, Tantec-UK provides an in-depth overview of plasma cleaning, including why you should use it, its benefits, the costs associated with plasma cleaning, and why you should invest in it.

Surface treatments are an essential part of many manufacturing processes. A large number of products made by industries around the world often bond different materials together, such as metal to plastic. Alternatively, others require long-lasting, high-quality printing on a plastic surface. In order to achieve this, the materials used often need to be contaminant-free to ensure an effective bonding process. One way we can achieve this is via plasma cleaning.

What is plasma cleaning?

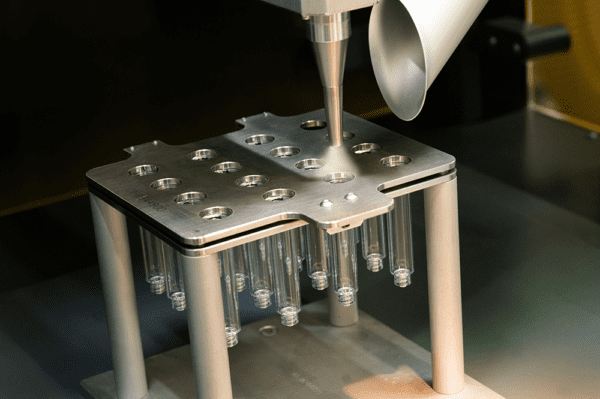

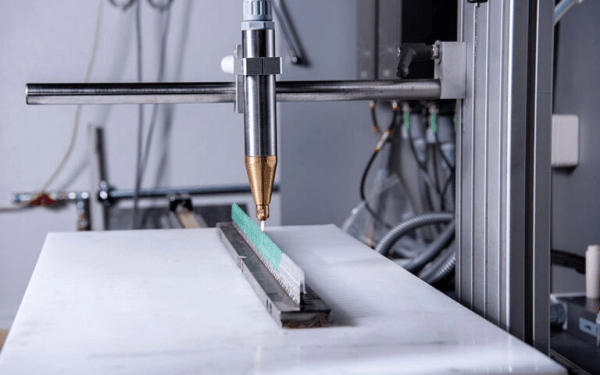

Plasma cleaning is the highly-effective method of removing contaminants from a surface in preparation for bonding or further processing. It eliminates organic and technical contaminants such as oils and grease, producing a clean surface in the process.

The plasma generates ultraviolet light that is incredibly effective at breaking down the organic bonds within surface contaminants, including oils and grease. When oxygen is also used in the cleaning chamber, it reacts with the organic contaminants, forming waste products such as water and carbon dioxide which are continuously removed from the chamber during the process.

Furthermore, a plasma cleaning system is also able to work with chemical functional groups including carboxyl, carbonyl and hydroxyl. These can render most surfaces as hydrophilic; this is when having a decreased amount of water contact angle – and an increase in wettability – enhances the bonding or adhesion to other surfaces during the manufacturing process. Finally, plasma cleaning is also highly effective in the removal of microbial contaminants from a surface – this is particularly effective for industries such as medical devices where materials need to be sterilised.

Why use plasma cleaning?

Plasma cleaning plays an integral role in the preparation of surfaces for bonding or further processing. It can be applied to a diverse portfolio of materials – as well as components that feature complex geometries. Ultimately the benefit of plasma cleaning is that, alongside removing natural and technical contaminants, it does not have any kind of negative impact on the properties present within a surface. This enables you to take complete confidence that the component or material still retains the same characteristics – just without those unwanted contaminants. For example, it is particularly effective at removing any outstanding mineral residue from the material’s surface.

What are the benefits of plasma cleaning?

One major benefit of plasma cleaning is that it can be used to prepare a multitude of surfaces, including ceramics, elastomers and plastics. It is also highly effective in the cleaning of glass and metal surfaces. There’s no doubt that it is an extremely versatile process.

Furthermore, the use of a world-class plasma cleaning system also avoids the need for the use of any chemical solvents. Not only is this substantially more friendly for the environment, but it’s also better for your operators. They’re no longer exposed to the hazardous risks that some chemical cleaning solvents pose. Don’t forget the amount of space taken up storing these solvents, or the costs incurred arranging for specialist waste disposal. There are clear benefits all round.

Of course, there’s always the cost-benefit aspect when exploring any technological change. In fact, plasma cleaning systems are rather inexpensive to operate. Not only this, but they also provide the highest quality surface cleaning solutions. They really do top the cost-benefit charts in comparison to any other form of surface cleaning technology.

What is the cost of plasma cleaning?

As we’ve touched upon, the cost of plasma cleaning equipment is favourable in comparison to other material surface cleaning systems available on the market. Not only is the upfront cost attractive, but maintaining the equipment year-on-year is also small. As a result, its popularity amongst manufacturers across the United Kingdom has soared in recent years. The best technology on the market at the most cost-effective price – who wouldn’t want that?

Invest in plasma cleaning

The benefits of plasma cleaning are clear. Not only is it a highly cost-effective technology, but it also offers the best material surface cleaning on the market. Whenever you need a clean and reliable surface, plasma cleaning is the process you should use. Don’t forget, it’s also environmentally friendly, safer for your employees and removes the pain and cost of arranging the responsible disposal of solvent waste. It’s a win-win situation.

As a trusted provider of plasma cleaning systems and surface treatment solutions for a diverse portfolio of customers across the United Kingdom, Tantec-UK is well-equipped to support you. Whether you want to purchase one of our innovative plasma cleaning systems or utilise our world-class sub-contract manufacturing services, we’ve got the solutions for you.

Tantec-UK wrote this blog. To read more blogs like this one, visit Tantec’s Knowledge Hub.

Tantec-UK

01527 304 004

Website

Email