Verus Precision Launch the Verus Integrated Process (VIP)

What if you could see a full ISIR metrology report on your moulded component months before mould tooling is built? Likewise, what if you could do accurate assembly analysis, failure tree and failure mode analysis and physical assembly of your as-moulded components combined with testing of downstream product handling and assembly lines?

And what if you could compensate for warpage deflections and reduce your time through validation and into production?

What would that be worth to you and your organisation?

Over the last twelve months the team at Verus have been working closely with several clients to develop a new innovative process which they believe has the potential to revolutionise the design and validation of injection moulded components.

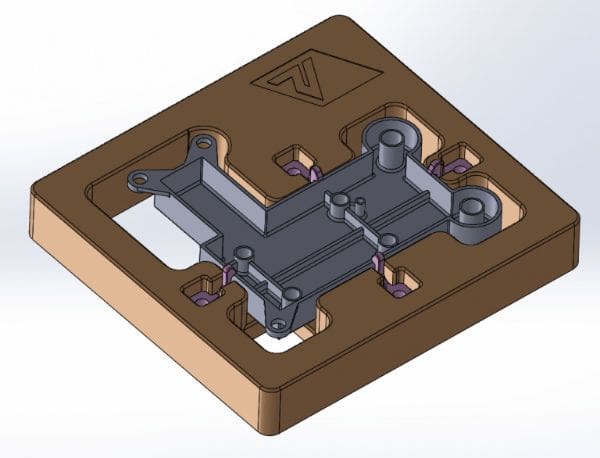

The Verus Integrated Process, or VIP as they call it, is the new pioneering integrated service that combines the power of Verus Precision’s world-leading bespoke Fixture Designs, Autodesk Moldflow Technology, off-line metrology CMM software and our 3D printing technologies.

It’s often the case that Fixture Design, Metrology, Moldflow and 3D printing are treated as four separate processes with their own specific goals. Not at Verus Precision, as they incorporate all these technologies, capabilities and experience and apply them to all their Metrology Fixture designs.

Verus believe that by integrating these services they offer customers the best of not one, but four worlds. It’s a holistic approach and it benefits clients as it allows their as-moulded component to be assembled into Verus Precision’s fixture designs and programmed off-line; then they can see a full metrology ISIR report before a physical moulded part has been created, and all in a virtual environment.

Click here to find out how it works.

Contact Verus Precision today if you would like to know more about this process or if you think Verus can help your organisation.

Verus Precision

+44 (0) 115 967 7807

Website

Email