Verus Metrology Sees Third Machinery Shipment Within 12 Months

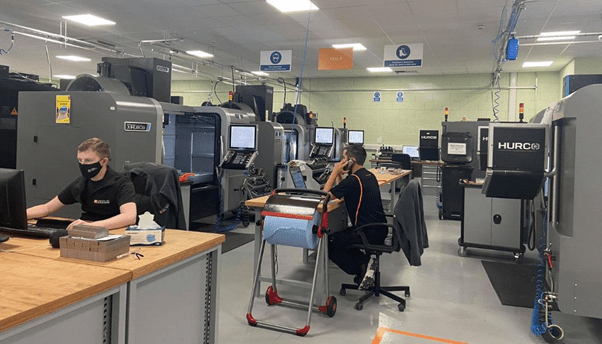

Verus Metrology Partners has received its third shipment of Hurco milling machines within twelve months, as the metrology solutions provider bolsters its manufacturing capacity with continued investment in state-of-the-art equipment.

Verus Metrology Partners’ strong reputation as the number one trusted provider of integrated turnkey metrology solutions has long been enhanced by continued investments in state-of-the-art technology.

One area that thoroughly relies on such advanced equipment is Verus’s leading manufacturing department. As a precision-led metrology equipment provider, Verus primarily relies on Hurco systems to manufacture fixtures for single component measurements right through to highly sophisticated, large multi-station metrology fixture solutions.

Increasing Manufacturing Capacity at Verus

The experts in measurement analysis recently received their third shipment of Hurco VM series milling machines in less than twelve months. As a result, the fixturing specialists now boast 12 machining centres, all dedicated to custom fixturing.

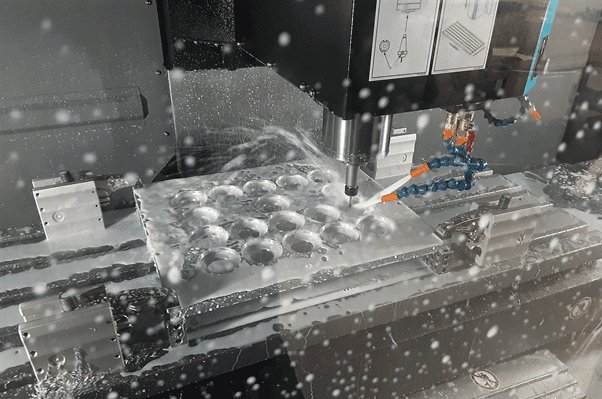

Verus utilises its large fleet of Hurco VM10i and VM30i milling machines to process high-quality metal parts for its bespoke metrology inspection fixtures. Implementing the fixtures’ exact specifications in no time, Verus certifies its position as integrated metrology solutions market leaders thanks to the quality of the machines used and the high number of repeat parts rapidly produced.

Verus Manufacturing Manager Colm Taylor says:

“We have a great relationship with Hurco as their machines are second to none in the market. The machine’s efficiency and ease of operation simply cannot be beaten in the milling of our highly complex fixtures.

“Orders are commissioned and carried out on-demand in STEM sectors. Production must start as soon as we receive the PO, as we are all too familiar with our client’s short production timeframes. Hence, it is only logical that the team is equipped with the most sophisticated of manufacturing machinery. We feel that Hurco understands this through the technology their advanced milling machines are fitted with.”

The Importance of Continued Investments to Meet Client Demands

Companies from the medical device and pharmaceutical, engineering and FMCG industries value this strict adherence to top-quality, accurate and reliable manufacturing. Thanks to Verus’s highly compliant manufacturing processes, the company, which has operations in Ireland, the UK, and the United States, meets even the most complex of fixturing requests quickly and reliably, with quality guaranteed.

Group Technical Operations Director Sean Murphy adds:

“By investing in the latest CNC technologies, we provide the right tools to our team to build some of the most innovative measurement solutions for the mass inspection of complex plastic component geometries.

“Collectively, we develop solutions and integrated software’s to deliver systems that hold anything from syringes and syringe components, glass vials and tubes, stoppers, caps and knee and hip metals to equator fixtures and programs. We are a team that solves measurement challenges and takes pride in the work that we do.”

Contact Colm Taylor on +353 71 91 43506 (ext. 213) for more information on Verus’s expert, in-house manufacturing facilities. Moreover, subscribe to their newsletter to receive technical blogs, customer updates, and all the latest developments.

![]()

Verus Metrology Partners

+44 (0) 115 967 7807

Website

Email