Velocetec Invests and Diversifies for Future Tooling Success

Leading UK toolmaker Velocetec has never been a company to stand still and let opportunities pass them by; this willingness to undertake challenging projects has seen the toolmaking department flourish over the past two years, driving investment and diversification of the manufacturer’s tooling capabilities.

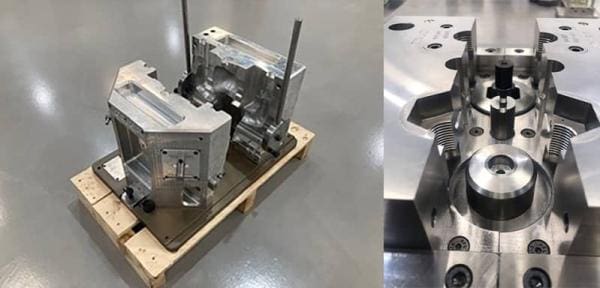

This diversification includes the addition of silicone mould tooling, rubber injection tooling, and compression mould tooling to Velocetec’s already impressive skillset, complementing the established injection mould tooling services undertaken by the business. The types of tools that Velocetec can produce are wide and varied, from rapid prototype aluminium automotive moulds, to fully hardened stainless steel medical tooling.

Velocetec’s Director Ben Yule commented on identifying the need to diversify,

“Being diverse and adaptable to producing different types of tooling allows the business to ‘level off’ the peaks and troughs of tooling projects with longer lead-times by supplementing them with rapid prototype, low volume, one-off tools, helping with cash flow into the business before being able to invoice some of the longer-term projects.”

New Employees, Familiar Faces

Late 2021 and early 2022 have seen the business bolster their tooling sales and design departments with the introduction of Malcolm Aldous as Sales Manager, and Adrian Chapman as Injection Mould Tool Designer. The introduction of these highly regarded and experienced engineers allows Velocetec to offer customers not only competitive costs and lead times, but invaluable Design for Manufacturing (DFM) considerations pre-production. These are two fantastic additions to the business, whose knowledge and contacts are second to none.

Investing in the Future of Tooling

January 2022 saw Velocetec hit the ground running with the introduction of two new GFMS Mikron milling machines to bolster production demands of their tooling department. These machines have become part of a dedicated ‘Toolmaking Cell’ which will focus on the production needs of their ever-growing customer base. The Cell is manned 24 hours a day by an experienced team of mould tool machinists, giving the company the ability to offer shorter lead times and monitored quality throughout the day and night.

Director Rob Carter explains how the introduction of these new machines has a massive impact on the productivity of a rapidly developing department,

“Recognising that mould tooling has now become an integral part of the business really was the driver for setting up and investing in a dedicated mould tooling machining cell. Having this cell allows us to tool the machines with the appropriate cutters, etc and have operators with mould tool specific machining skills driving productivity and quality.”

The Year Ahead…

Velocetec look forward to another successful year ahead, building on the relationships forged with existing customers and developing new partnerships with businesses, helping all to realise their tooling requirements. Get in touch with Velocetec now to discuss your tooling project.

Velocetec

023 9400 2002

Website

Email