Trotec Launches Vision Design&Position Camera

Trotec Laser has upgraded its flagship laser cutting and engraving machine with Vision Design&Position, a new lid camera designed to save even more time during laser processing.

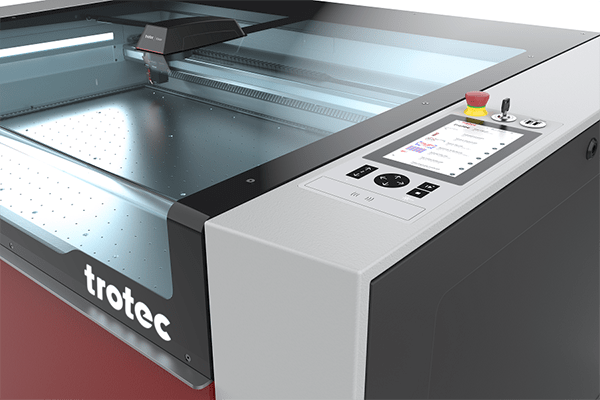

The Speedy 400 Run on Ruby® laser system is already the fastest of its kind, with cutting speeds up to eight times faster than other systems. The new 12 megapixel patent-pending Vision Design&Position lid camera further speeds up workflow by delivering a live image of the entire work area onto the operating PC in real-time.

A full colour and detailed image of the laser bed and workpiece is displayed within Trotec’s proprietary Ruby® software, allowing the laser operator to position the artwork file exactly where they’d like it to be cut or engraved, and to see a visual representation of how it will look before the job is started. This new feature negates the need for manual positioning of the laser pointer and saves graphic position data to the software, making laser job setup faster and easier than ever before.

The Vision Design&Position camera is the latest feature to be added to the Ruby® software which incorporates all design and preparation stages of the laser cutting and engraving process to drastically reduce the time and cost of the workflow. The software is under continuous development by Trotec with more time-saving features being planned for future releases.

Trotec’s Speedy 400 Run on Ruby® laser system boasts a touch screen operation, thanks to Ruby®, making it possible to operate the laser in the network via Ethernet or WiFi without an additional PC. The versatile 1016 x 610mm working is suitable for many standard sheet sizes while power options up to 120 watts and a maximum processing speed of 4.3m/s make the Speedy 400 a highly productive professional-grade cutting and engraving system.

All Trotec Speedy systems are available with a range of accessories in addition to CO2, fibre and flexx laser source options and are fully supported by a UK-based technical service team. For more information, visit www.troteclaser.com or call +44 (0)191 580 1182.

Trotec Laser

+44 (0)191 580 1182

Website

Email