BOY: The BIG Name in Small Machines

|

Getting your Trinity Audio player ready...

|

BOY Ltd has unveiled its upgraded PRO range of injection moulding machines, providing a cost-effective alternative to other models in its portfolio. This newly improved series includes the advanced Procan ALPHA 4 control system, a conventional water distributor, and the energy-saving Servo-Drive as standard features across the E series.

The PRO range, which is designed with energy efficiency and productivity in mind, aligns with BOY’s longstanding philosophy of offering compact, space-saving machines. Each model in the PRO line boasts a small footprint, ensuring it integrates seamlessly into production environments where space is at a premium.

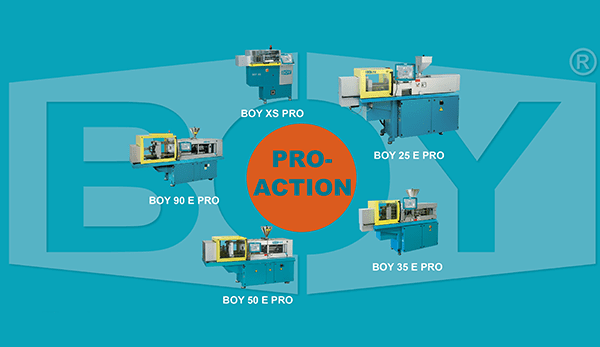

Comprised of five models—XS PRO, 25E PRO, 35E PRO, 50E PRO, and 90E PRO—the PRO series offers a streamlined selection of machines. These models are now equipped with the well-established ALPHA 4 control system, making them a robust and efficient choice for manufacturers. The carefully curated range not only enhances operational efficiency but also delivers on BOY’s commitment to compact and effective design.

In addition to the PRO series, BOY Ltd’s broader range of injection moulding machines, which offers clamping forces from 6.3t to 125t, now comes equipped with the latest ALPHA 6 control system and electric waterflow technology as standard. These innovations further enhance the versatility and performance of BOY’s machines, offering customers a wide array of optional extras to tailor each machine to their specific needs. Notably, all new BOY machines, including the PRO range, are fully Industry 4.0 ready, supporting the seamless integration of automation and digital technologies in manufacturing.

BOY Ltd also offers a vertical range of machines, featuring clamping forces from 10t to 60t. These machines are available with a variety of configurations, allowing for both vertical and horizontal clamping and injection units. This flexibility ensures that BOY machines can meet the demands of various applications across the plastics industry.

For those looking for a complete injection moulding solution, BOY Ltd offers turnkey packages through its ‘One Stop Shop’ approach. Ancillary equipment from its sister company, Hi Class Machinery Ltd, can be combined with BOY’s injection moulding machines, offering customers a comprehensive solution tailored to their manufacturing needs.

BOY Ltd invites prospective clients to visit their Northamptonshire showroom to see the enhanced PRO range in action or to experience the latest ALPHA 6 control system firsthand. To schedule a demonstration, customers can contact BOY Ltd directly and arrange a visit.

Read more news from BOY Ltd here.

BOY Ltd.

01933 354460

Website

Email