Techniplas and KraussMaffei Build New MXW 1000 ColorForm System

To meet the sustainability needs of the automotive industry, Techniplas has partnered with KraussMaffei to manufacture the new MXW 1000 ColorForm system, which combines injection moulding technology and surface finishing with polyurethane in a single step.

“ColorForm technology holds great potential for a lower CO2 footprint in the production of components with a finished multifunctional surface,” explains Michael Fuchs, Global Application Owner Surface & Lightweight at KraussMaffei. Now the technology once more demonstrates its strengths at Techniplas, a well-known provider of sophisticated plastic components for the automotive and plumbing industries. In Treuen, Saxony, in the Vogtland region, a KraussMaffei MXW 1000 ColorForm system for the series production of components with a transparent surface has been put into operation.

Process expertise and quality awareness are the keys to sustainable production in the automotive industry. The wealth of experience of Techniplas as the user and KraussMaffei as the provider of injection moulding technology and PUR/PUA processing systems makes solutions possible that become increasingly more significant these days. ColorForm, that is, the ingenious fusion of injection moulding technology and surface finishing with polyurethane in a single process step is one such solution.

ColorForm: Coating right in the mould

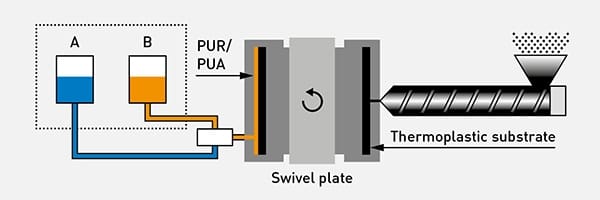

The ColorForm process is based on a combination of injection moulding and polyurethane processing. The tried-and-tested multi-component injection moulding procedure is the foundation of this process. What is special about it: After injection moulding the thermoplastic mould base body, this body is flow-coated with polyurethane (PUR) or polyurea (PUA) as the surface material in a second cycle.

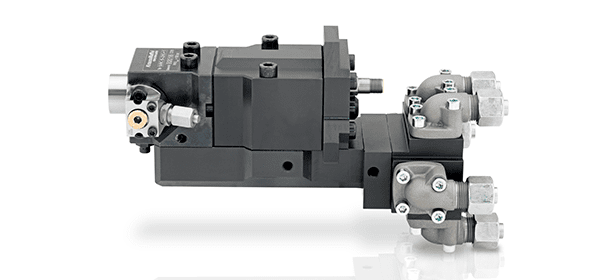

The RimStar Flex ColorForm reaction process machine, which was designed specifically for this process, and the mixing head feed the surface material (PUR/PUA) directly into the cavity. “RimStar systems take up very little space and meter even small amounts precisely and at a high clock frequency,” explains Philipp Strasser, Global Application Owner RPM & Automotive at KraussMaffei.

Transparency with depth effect

“On this system, parts are produced in the injection-compression moulding process. To obtain a special depth effect, a premium-quality, transparent PUR surface is applied to these parts,” explains Toni Luckner, Process Developer in Treuen (Vogtland). “One more system for the project will be put into operation in the first quarter of 2022.”

“Our customers, large OEMs from the automotive industry, have stringent requirements regarding quality. There must not be any deviations greater than 0.2 mm on any part of the transparent component. Using the MXW 1000 in combination with the RimStar Flex for PUR metering, we fully meet these requirements,” says Luckner.

Techniplas has had positive experiences with the ColorForm technology from KraussMaffei for many years now. At Techniplas, the technology is called ‘ColorFuse.’ The company currently has four ColorForm systems in Treuen and one in Rüti, Switzerland. This system has been manufacturing ColorForm parts in series production since 2016.

In addition, their in-house TechCenter in Treuen operates two more systems.

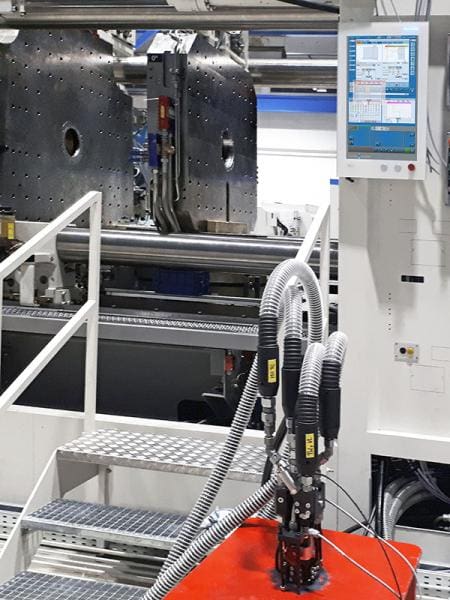

Production in the cleanroom

“We run this production process under cleanroom conditions. Thus, not a grain of dust can sneak in between the coating and the substrate surface while the mould is open.” Accordingly, the entire system is equipped with a cleanroom enclosure. “In this way, we achieve very low scrap rates,” emphasises Luckner.

Efficient and sustainable production

Initially, ColorForm was developed for greater production efficiency and specific effects for interior vehicle components. At Techniplas, the MXW 1000 ColorForm system puts those qualities on full display. Today, however, aspects such as workplace safety and the CO2 footprint of the technology compared to other production methods are becoming more and more important. Again, the ColorForm process scores points here in multiple areas. Moreover, ColorForm components are increasingly used even in the exterior area because here as well, a classy appearance is a selling point for end customers.

Increased potential for saving

Using ColorForm technology eliminates Techniplas’ need to transport and paint components and invest in a painting plant. The finished components are also ready for installation when discharged from the automated production cell, saving on buffer storage and drying.

Upgrade in difficult times

For the system that has been put into operation now, Techniplas used an existing MXW 1000 injection moulding machine from KraussMaffei as the basis. Techniplas had the MXW retrofitted at its manufacturer’s main factory in Munich’s Allach neighborhood.

“There, all necessary equipment is available on-site, and commissioning at the TechCenter was also completed on schedule – both for the injection moulding machine and for the PUR technology, that is, for the RimStar Flex with two MK 5-2K CCM mixing heads for simultaneous production of two components. This cannot be taken for granted under the current basic conditions determined by the pandemic,” says Luckner.

New control system and ORCA cooling

The MXW 1000 was not just retrofitted for ColorForm technology. Its control system was also completely upgraded to the MC6 control system, and a new ORCA cooling system was installed.

“The system performs a contact-free temperature measurement, which minimises maintenance. The technology allows us to control the twenty cooling circuits of the MXW precisely and thus makes a critical contribution to the high, uniform quality of the components,” explains Luckner.

Visit kraussmaffei.com/en/home to learn more about the industries KraussMaffei caters for and its various technologies and products offered. Alternatively, click here to read more news from KraussMaffei.

KraussMaffei

+44 (0) 1925 644100

Website

Email