Tappex Launch 3rd Generation Heat Inserter

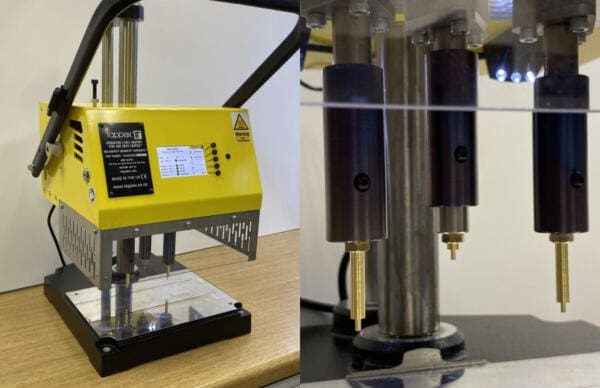

The Tappex Generation 3 heat inserter has been designed to allow quick, easy and repeatable installation of a range of Tappex threaded inserts into plastic moulds.

The Tappex® Generation 3 Heat Inserter allows easy installation of a range of Tappex threaded inserts – Multisert®, Microbarb®, Dedsert® and Suresert® female and male inserts.

The machine comes as standard with one heater cartridge but is capable of installing up to 4 inserts, at multiple heights at one time with additional cartridges fitted.

Key features:

- Switched operator and setter modes.

- Secure, lockable setting enclosure.

- Installation speed control.

- Depth verification Indicator light.

- Variable temperature up to 400 C.

- Adjustable stop position.

- Operation handle suitable for left or right-hand operation.

- Complete with 3 standard heat tips to suit Tappex inserts, selected at time of order.

- Removable power lead with 2 or 3 pin plug fitted. (Customer to specify at time of order.)

- Machinable base plate and top plate for jigs and fixtures.

- Twin mounting columns for increased stability.

- Maximum working height with tip removed 220 mm. (Standard tips protrude approximately 25 mm.)

- Work Area of 210mm x 300mm illuminated by dual LED lighting.

- Stroke length – 70 mm

Tappex was recently approached by a local moulding company regarding a new, large-volume moulding project that they were working on for a major automotive OEM. The customer had a particularly tricky mould design that required 4 threaded inserts to be heat installed, post mould. After assessing the available tooling solutions, they approached Tappex to see what they could offer.

The Tappex Engineering Team assessed the drawings and produced a bespoke, multi-point solution for the moulder allowing them to secure the business with the OEM. A further 3 units are planned for purchase which will dramatically reduce the installation time on other projects.

Tappex is proud to have been manufacturing in Britain for over 60 years and offer a range of thread insert and installation tooling solutions for plastic injection mould applications. For more information, visit the company website.

Tappex Thread Inserts Ltd

01789 206600

Website

Email