Talisman Switches to 24/7 Operation Using Intouch i4 Cloud

Talisman Plastics has switched to 24/7 operation to meet the increased demand for medical components for the NHS, enabled by the remote features of the Intouch i4 Cloud, which was installed on all 27 of its moulding machines in 2019.

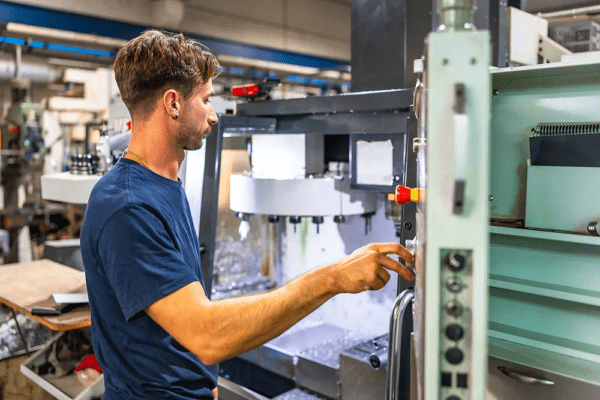

Talisman Plastics is a state-of-the-art manufacturer with nearly 100 years of experience of producing injection moulded products for a wide variety of sectors including aerospace, medical, automotive, electronics and white goods.

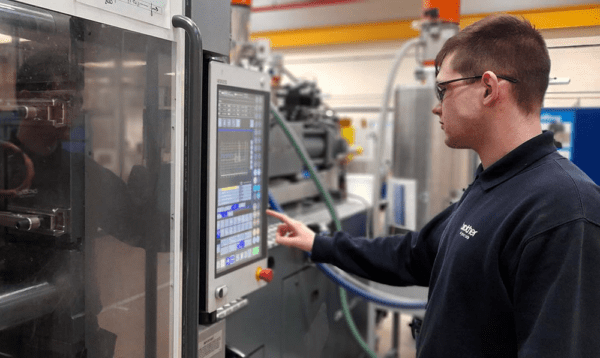

Talisman’s ethos is ‘doing the right thing for the customers’ and, in order to ensure that they meet the increased demand for medical equipment due to COVID-19, they have switched their medical equipment machines to 24/7 operation. The Intouch i4 Cloud allows them to leave the machines completely unmanned during the 48 hours of the weekend, increasing production whilst keeping their staff safe.

Using the Intouch i4 Cloud, Talisman staff can remotely access the following with their phones (or on other devices such as laptops and tablets) :

- Mimic displays which show real-time machine status and the shift profile

- Clicking on the virtual machines gives them more detailed information about the machine

- Downtime alerts were created (in the form of emails sent to designated users)

Following their first unmanned weekend, Talisman Production Manager, Ewelina Skalska said:

‘We have found it extremely useful, and it helped us to reduce downtime to a minimum – The downtime reports listing the reasons for downtime, the shift profile – how many times machine stopped within the shift and why! And of course, recently the mobile phone option, where we can remotely monitor machines downtime. Email alerts letting us know when machines have been stopped for longer than 30 minutes is a massive improvement and it helped us to improve BT Cells (NHS) machines efficiency from approx.. 75% to over 95%!’

‘We are very impressed with Intouch customer service – especially with Lucy, who always comes back to us within 1 hour or so and is always ever so helpful. We are amazed how quickly Lucy managed to help us set up Intouch on our mobile phones for several users and machine downtime alerts last Friday – especially at such a critical moment, where we have Hospitals chasing us for parts (BT Cells machines).’

On the whole, Talisman Plastics have found that Intouch has greatly improved their operational efficiency:

‘We run weekly reports based on the Intouch data to review and feedback on utilisation and OEE – we have a set of targets to achieve and for example, with utilisation we managed to improve it by over 5% (less than 62% in the past, an average of 67% since Intouch & new Intouch scheduling system implemented).’

Other Intouch features and functions regularly used by Talisman is the schedule for planning, monitoring cycle times, OEE as well as most importantly downtime and the reasons for it. They also monitor quantities produced against each works order and for monitoring scrap.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email