In this blog post, RJG goes into more detail on the causes, prevention, and troubleshooting of short shots in plastic Read More

Tags :rjg

RJG is excited to announce an innovative new feature for their CoPilot®process control system called MAX, the Process Advisor™. Read More

We talk a lot about injection moulding process optimisation, but what does that entail? What parameters need to be perfected Read More

RJG is now offering a new data migration tool so eDART® users can transfer their data to the CoPilot® quickly Read More

RJG‘s 2024 annual RJG Mould Smart Award is now open for applications. The goal of the Mould Smart Award is Read More

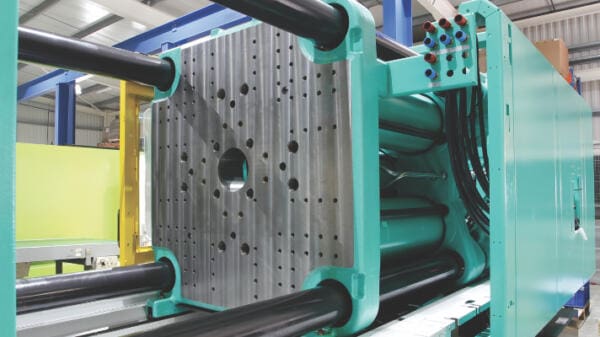

Clamp force is one of the most overlooked portions of the Injection Molding process. I can’t count how many Read More

Injection pressure is a crucial parameter in the process of injection moulding. Injection pressure builds by the force of the Read More

RJG is pleased to announce the Europe winner of the second annual RJG Mould Smart Award™, Technimark GmbH.Read More

When looking at injection moulding cavity pressure sensors, the sheer number of products to choose from can be a bit Read More

There are a lot of ways to reduce how much material is in your automotive parts—some easier than others. Read More