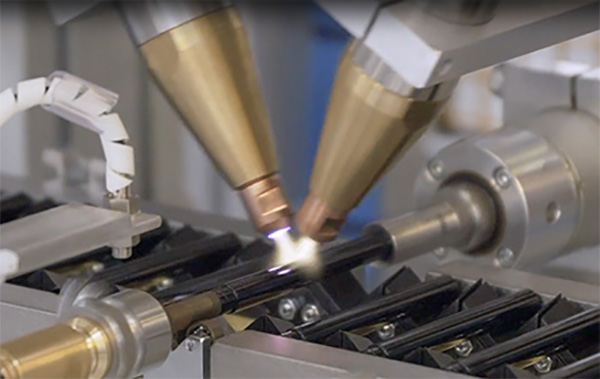

Surface Treatment with Plasma Replaces Unreliable Flame Treatment

After many years, the Italian machine manufacturer GPE Ardenghi Srl has replaced flame treatment with Tantec‘s plasma treatment in their screen printing machines.

GPE Ardenghi Srl, a family-owned business, was founded in 1945. The company has specialised in semi-automatic and automatic equipment for complex screen printing machines for promotional items, cosmetics, pharmaceutical, automotive, and other industrial groups. A common customer established the contact between Tantec A/S and GPE, which resulted in a constructive dialogue on the use of plasma in GPE’s equipment. After several meetings, trial runs, and implementation, GPE decided to include a Tantec solution as their standard option for their screen printing machines.

”We are extremely satisfied with Tantec’s product quality. In combination with Emme Zeta imp.’s high service level, this is very special and crucial for our collaboration,” says Mr Roberto Ardenghi, GPE Ardenghi Srl.

At Tantec, we are experiencing an industry trend of replacing flame with plasma treatment. A growing number of customers are moving away from flame treatment because of its high carbon emissions and the dangerous working environment. With Tantec’s plasma surface treatment, you can achieve a greater ROI than with flame treatment, which is more expensive due to its high power consumption.

Customers also ask for alternatives to unreliable flame treatment because they have little control over the entire process. The lack of control is a significant problem for the production process since it often leads to defects in the final product. There are also complaints of a lack of consistency in the results generated by flame treatment systems. Depending on the manufacturers’ quality standards, results have ranged from acceptable to very poor.

The first of many solutions from GPE and Tantec have already been delivered to different industries, and we have only been receiving positive feedback.

Furthermore, the Italian machine manufacturer has been delighted with the high degree of flexibility in the cooperation with Tantec:

”Due to the special requests of our customers and our machines which are often customised, it’s absolutely an extra value, the assistance and the good cooperation we have with both Emme Zeta and Tantec. The way they try to solve our need is something essential to grant quality and performance on our automation solutions,” says Mr Roberto Ardenghi.

Tantec offers standard and customised equipment to be integrated as a part of the production process and can be integrated into new or existing on-line production environments.

Tantec has been creating Plasma and Corona treatment systems since 1974, with its advanced, modern manufacturing facilities in Denmark it has worked closely with customers around the world to become a truly global manufacturer of the highest quality surface treatment equipment.

To find out more about Tantec’s surface treatment solutions, visit the company website.

Tantec-UK

01527 304 004

Website

Email