Summit Systems Partners with AMTEK Plastics to Reduce Waste and Enhance Automation

|

Getting your Trinity Audio player ready...

|

AMTEK Plastics, a UK-based plastic manufacturer, was facing inefficiencies due to unused sprues being discarded during production. The accumulation of waste led to increased storage requirements, higher labour costs, and unnecessary material loss. To tackle these challenges, Summit Systems, a leading provider of plastics automation solutions, stepped in to assess the situation and implement an efficient, automated recycling system that would minimise waste and streamline operations.

Summit Systems conducted a trial using two different granulators to identify the most effective solution for the manufacturer’s needs. Through this process, Summit’s team carefully assessed key performance factors, including efficiency, integration capabilities, and ease of maintenance, to ensure the best possible fit.

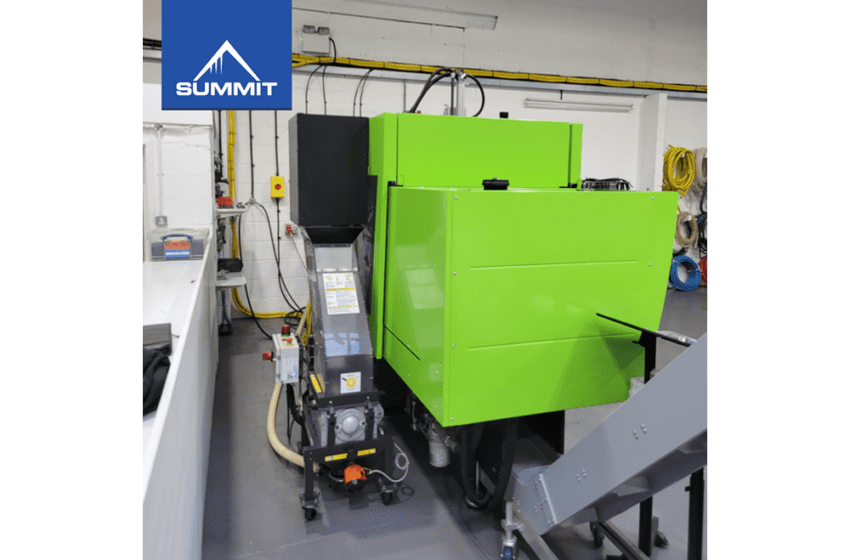

Following the trial, the MO-DI-TEC Slow Speed Granulator was selected due to its multiple advantages. This advanced system provided significant noise reduction for a quieter working environment, low dust production to maintain material quality and cleanliness, and easy cleaning to simplify maintenance and reduce downtime. Additionally, it required minimal maintenance, enhancing overall operational efficiency, and featured an integrated metal detection system to prevent contamination and protect the injection moulding machine (IMM) from costly damage.

Once installed, the MO-DI-TEC Slow Speed Granulator was fully integrated into the production process, with Summit Systems overseeing the implementation to ensure seamless operation. To maximise efficiency, the granulator was connected to machine loaders via proportioning valves, allowing for the automatic reuse of scrap polymer and the creation of a closed-loop recycling system. This automation eliminated the need for manual intervention, reducing labour requirements and ensuring a consistent, reliable process.

Summit Systems also ensured full integration with the manufacturer’s robotic systems, further enhancing efficiency and streamlining material handling. As a direct result of this upgrade, the company achieved a waste reduction of 15-18%, significantly cutting material loss and disposal costs while improving its overall sustainability efforts.

Encouraged by the success of this implementation, the manufacturer is now exploring the possibility of expanding the solution across additional machines, further reducing scrap, lowering costs, and increasing process automation. By partnering with Summit Systems, they have not only improved efficiency and waste management but also established a more sustainable and cost-effective production process. This project highlights Summit Systems’ expertise in delivering tailored automation solutions, helping manufacturers enhance productivity, reduce waste, and achieve long-term operational improvements.

Discover more from the MO-DI-TEC range of Slow Speed Granulators.

Read more news from Summit Systems here.

Summit Systems

+44 (0)1827 265 800

Website

Email