Summit Systems Celebrates 35 Years of Innovation and Excellence

|

Getting your Trinity Audio player ready...

|

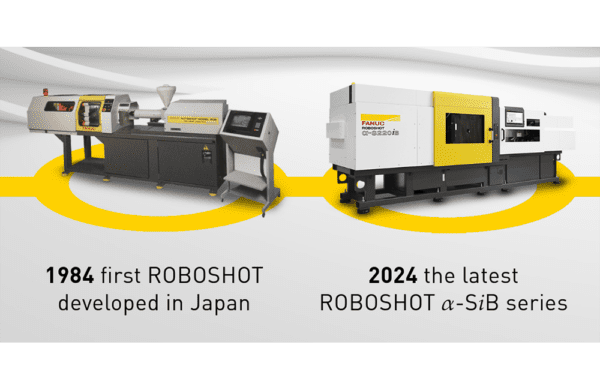

This year, Summit Systems celebrates its 35th anniversary, reflecting on three and a half decades of pioneering achievements, unwavering dedication, and continued growth in the plastics industry. Since its founding in 1989, Summit Systems has remained at the forefront of innovation, consistently delivering innovative solutions and unparalleled service to its customers through a meticulously selected range of plastics auxiliary equipment.

From humble beginnings in 1989 to its current position as a leading provider of plastics automation and auxiliary equipment, its journey has been one of constant evolution and adaptation to meet the ever-changing needs of the industry. Over the past 35 years, Summit Systems has expanded its product offerings, forged strategic partnerships, and embraced emerging technologies to better serve its customers and drive progress within the sector.

Summit Systems’ extensive range of auxiliary equipment is designed to enhance efficiency, productivity, and sustainability in plastics processing. Its offerings include:

1. Material Handling Systems:

Conveying Systems: Summit Systems provides state-of-the-art conveying systems that ensure the efficient and reliable transport of raw materials within the production environment.

Pneumatic Conveying: Ideal for moving bulk materials over long distances, its pneumatic conveying systems are designed for durability and efficiency.

2. Drying Solutions:

Desiccant Dryers: These advanced dryers remove moisture from hygroscopic plastics, ensuring optimal material properties and product quality.

Compressed Air Dryers: For smaller throughputs, compressed air dryers offer an energy-efficient solution.

Vacuum Dryers: The vacuum dryers provide rapid and energy-efficient drying, significantly reducing drying times while maintaining material integrity.

3. Blending and Dosing Equipment:

Gravimetric Blenders: Accurate and consistent blending of multiple components is achieved with gravimetric blenders, which are essential for maintaining product quality.

Volumetric Dosing Units: These units provide precise dosing of additives and masterbatches, ensuring consistent product characteristics.

4. Temperature Control:

Mould Temperature Controllers: Advanced temperature controllers maintain precise mould temperatures, crucial for the quality and efficiency of injection moulding processes.

Water Chillers: Energy-efficient water chillers ensure optimal cooling for various applications, enhancing the productivity and longevity of machinery.

5. Granulation and Recycling:

Granulators: Summit Systems offers robust granulators that efficiently reduce plastic waste into reusable granules, promoting sustainability and cost savings.

Shredders: Designed for larger plastic waste, shredders provide an effective solution for reducing bulk materials into manageable sizes for recycling.

6. Robotics and Automation:

Pick-and-Place Robots: These robots increase efficiency and precision in handling moulded parts, reducing labour costs and improving consistency.

Automated Systems: Fully integrated automation solutions streamline production processes, enhancing overall plant efficiency.

As Summit Systems celebrates this milestone, it remains committed to driving innovation and excellence in the plastics industry. The company’s dedication to customer satisfaction, environmental sustainability, and technological advancement has cemented its reputation as a trusted partner and leader in the field.

Summit Systems’ continuous investment in research and development ensures that it stays ahead of industry trends and offers cutting-edge solutions to its clients. By embracing emerging technologies such as Industry 4.0, Summit Systems is poised to lead the next wave of innovation in plastics processing.

Summit Systems’ success over the past 35 years is a testament to its adaptability, expertise, and unwavering commitment to excellence. As the company look to the future, it is excited to build on this legacy, continuing to provide innovative solutions that drive progress and create value for Summit’s customers.

For more information on Summit Systems and its comprehensive range of plastics auxiliary equipment, please visit Summit System’s website.

Read more news from Summit Systems here.

Summit Systems

+44 (0)1827 265 800

Website

Email