Summit Fabrications Opens State-of-the-Art Facility to Serve Plastics and Process Cooling Industries

|

Getting your Trinity Audio player ready...

|

Summit Fabrications, a division of Summit Systems, proudly announces the relocation to a state-of-the-art 17,000-square-foot facility at Unit 22 Darwell Park, Mica Close, Tamworth, B77 4DR. This significant expansion, more than tripling the size of its previous 5,000-square-foot premises, highlights the company’s commitment to innovation, growth, and delivering excellent service to its customers in the plastics and process cooling industries.

After 11 successful years at the Apex Business Centre, Summit Fabrications has outgrown its former site. The new facility is designed to meet the increasing demands of its customers while positioning the company for future growth. With a focus on advanced manufacturing capabilities, operational efficiency, and sustainability, the new premises provide the infrastructure to support an expanded range of products and services.

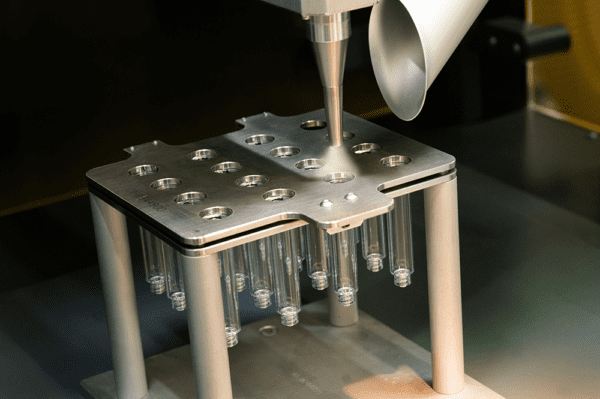

The facility has cutting-edge tools and machinery, including a plasma machine for precision metal cutting, a bandsaw, a punch press, and a spot welder. A key addition is a new spray-painting booth, which allows the company to finish fabricated items in any RAL colour, providing greater customisation for customers. Welding remains at the core of the business, and the expanded space enables the team to easily handle larger and more complex projects. Future plans include upgrading the plasma machine to a laser cutter, further enhancing precision and efficiency.

The facility is equipped with cutting-edge tools and machinery, including a plasma machine for precision metal cutting, a bandsaw, a punch press, a spot welder, and a key addition is a new spray-painting booth. Welding remains at the core of the business, and the expanded space enables the team to handle larger and more complex projects with ease. These upgrades mean Summit Fabrications can now handle a wider variety of projects, from bespoke one-off pieces to production of standard items such as Material Storage Bins and Big Bag Frames.

This relocation not only increases production capacity but will also allow Summit Fabrications to stock high-demand items for next-day delivery. Historically, all items were built to order, but the larger facility now supports mass production of standard items such as Material Storage Bins and Big Bag Frames. This capability reduces lead times and provides customers with faster access to essential products.

Rebecca Evans, Fabrications Manager, expressed her enthusiasm for the move, stating, “This new facility is a game-changer for Summit Fabrications. It reflects our dedication to meeting the evolving needs of our customers while staying at the forefront of fabrication technology. By investing in this space and the latest equipment, we’re ensuring that we can deliver higher quality, faster turnaround times, and a broader range of services.”

The expanded capabilities also allow Summit Fabrications to diversify its offerings. While the company continues to serve plastics and process cooling customers, it is now better equipped to cater to industries such as medical, automotive, and general material handling. New product lines include De-dusting Systems, Water Pump Skids, and a budget-friendly range of Storage Bins designed for stock availability and next-day delivery. These solutions are ideal for businesses dealing with raw materials and industrial process cooling.

The facility also serves as a hub for collaboration and innovation. Customers can visit the site to work directly with the technical and design teams, ensuring that bespoke solutions meet their exact requirements. This hands-on approach enhances customer satisfaction and strengthens long-term partnerships.

Beyond its operational benefits, the new facility has a positive impact on the local economy. Summit Fabrications plans to grow its team, creating job opportunities in the Tamworth area.

Sustainability is also a key focus for Summit Fabrications. The facility features energy-efficient equipment, and plans are underway to upgrade existing machinery to more environmentally friendly alternatives. This commitment aligns with Summit Systems’ broader mission to innovate responsibly while supporting the industries it serves.

For over 17 years, Summit Fabrications has been a trusted partner in the plastics and process cooling industries, delivering bespoke fabrication solutions that enhance efficiency and performance. This new facility represents a bold step forward, providing the capacity and technology needed to support customers across diverse industries while laying the foundation for long-term growth.

Read more news from Summit Systems here.

Summit Systems

+44 (0)1827 265 800

Website

Email