New Strack Quick Clamping Systems Slash Set-up Costs

Represented by Hales in the UK and Ireland, Strack Normalien has expanded its range of quick clamping systems with two variants, Z8061 and Z8062, offering innovative solutions to reduce set-up costs and create high flexibility for customers due to quick and easy tool exchange.

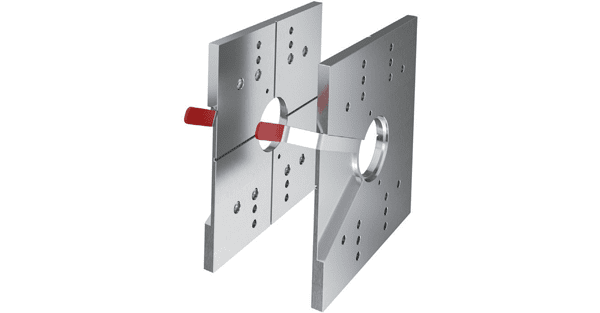

Tools are positioned and clamped in the injection moulding machine quickly and easily through the Strack Normalien quick clamping systems. The fixed connection of the system clamping plates with the tool is made via a torsion-free clamping using inclined eccentrics. The proven mechanical system for injection moulds is suitable for two- and four-bar versions of all market-leading manufacturers. The quick clamping system can be used up to a maximum clamping force of 1000 kN and a total weight of 1000kg. In addition, depending on the injection type, they can be used universally, horizontally, or vertically.

According to Euromap 2, the quick clamping system has eight fastening holes per plate as standard. In addition to its standard system, Strack Normalien now offers two new variants: the system Z8061 is designed for the common bar distances of the injection moulding machines, while Z8062 covers the complete clamping plate of the injection moulding machine, also between the bars.

The retrofitting effort for existing injection moulding tools is low since only the existing centring flanges have to be exchanged with the special centring flanges Z8071/ Z8073. No new clamping plates have to be produced. The retrofitting is quick, easy, and cost-effective, as no hydraulic or electrical interfaces to the injection moulding machine are required.

The clamping of the mould is done in a few seconds without excessive force. From the operator side, the clamping lever is manually moved via a bayonet fastening. The clamping by simply moving two levers instead of the time-consuming use of clamping claws respectively screwing to the clamping plate of the injection moulding machine significantly reduces the set-up time considerably.

In addition, Strack Normalien also manufactures special versions according to customer requirements, with and without bar recesses, up to a plate size of 796mm x 696mm. Also, versions such as, for example, special screw-on or tempering holes are possible upon agreement.

Strack Normalien is a family-run developer and manufacturer of innovative standard parts and solutions for the global mould-making industry.

Established in the year 2000, Hales Tool & Die represents European suppliers of mould components and accessories. Hales is a distributor and support partner for Mastip, Strack Normalien and Vega in the UK and Ireland. To find out more, email sales@halestooling.com or visit the Hales webshop.

Hales Tool & Die Ltd

+44 1621 859141

Website

Email