RWC (UK) Ltd Opt for Tie-Bar-Less Technology

Following extensive market research and the use of a trial machine, RWC (UK) Ltd (formerly John Guest) has completed the purchase of five new injection moulding machines, ordering from ENGEL UK for the first time.

John Guest, an RWC brand, is a world leader in plastic push-fit fitting technology for many sectors including plumbing and automotive and is a repeat winner of the Queen’s Award for Export.

In the UK, there are currently 175 injection moulding machines working a 24/7 operation and RWC are implementing a programme of replacement for the older models. The company undertook extensive market research and testing before deciding to order five new machines from ENGEL UK.

RWC (UK) operates a vertically integrated supply chain, meaning that a product’s complete journey from initial concept, through to product manufacture, assembly and testing, is carried out internally. This philosophy gives the company ultimate control over the quality of the product and enables them to react quickly to market trends and customer requirements.

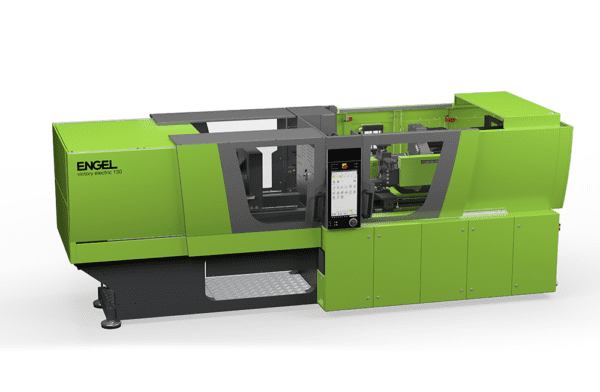

ENGEL, world-renowned for its tie-bar-less technology, offers a machine that can support RWC (UK) in their manufacturing goals. The tie-bar-less model allows greater efficiency and economy for moulders. Its lack of tie-bars simplifies mould changes as the moulds can be removed and mounted extremely quickly without hindrance to access and provides excellent mould protection.

Richard Horn, Project Lead at RWC (UK) says “Tie-bar-less technology provides us with great agility. It provides easier access for our setting staff and will save us time. The reduced energy consumption of the ENGEL machines has also been a factor in our choice.

“ENGEL UK provided us with a 50-tonne machine on trial, and so we were able to test its capabilities against our requirements. It was obviously important to us that there should be no compromise in part quality. We have seen that it does not matter if the cavities are located at the centre or the edge of the surface of the mould mounting platen, they all are subject to exactly the same level of clamping force, providing consistently high-quality parts.”

RWC (UK) have praised the customer service they have received from ENGEL UK, and are confident that the online support offered by the ENGEL e-connect.24 will provide them with any technical back-up they may need.

Steve Taylor, of ENGEL UK, comments “It has been a rigorous process for RWC (UK) and ENGEL UK fully appreciate the importance of such a decision. We have been happy to work with Richard Horn and his team to introduce them to ENGEL tie-bar-less technology and demonstrate how these injection moulding machines will make a real difference to their operation.”

ENGEL

+44 (0) 1926 335000

Website

Email