Russell Roof Tiles – Intouch Case Study

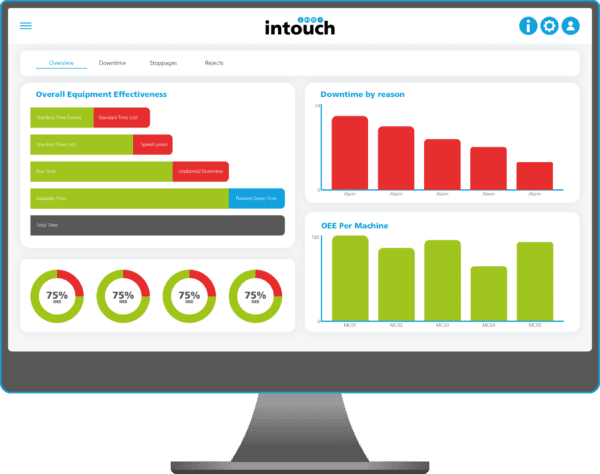

Russell Roof Tiles recently invested in new technology to streamline its manufacturing. Intouch Monitoring is a production monitoring system that will help the team focus on key downtime hotspots, assess potential efficiency gains, and will help strategic purchasing decisions.

The new system is being used at Russell Roof Tiles (RRT) dedicated plastics site on Wetmore Lane in Burton. It enables the firm to acquire real-time data on its injection moulding machines, which produce the company’s UPVC accessories, including its popular dry verge systems.

With the new system, data taken from RRT’s equipment will enable the production team to make informed decisions quickly on increasing efficiencies and output. The technology, used worldwide, will allow Russell Roof Tiles to closely monitor performance, ensuring they operate at optimal levels with minimal downtime.

Dan Hancox, Business Support Manager at Russell Roof Tiles, has led the project as part of the company’s wider initiative to reduce waste and maximise overall equipment effectiveness (OEE).

Dan commented: “We’re excited to have implemented the Intouch Monitoring technology. The system has proven to be highly reliable and accurate, and we are confident in its capability to help us drive operational excellence, achieve our production targets, and maximise efficiency.”

With phase one of implementing the monitoring system now complete, the second phase of investment will include monitoring energy consumption of all individual machines, allowing the company to find ways to use them more efficiently and at more cost-efficient times. This sustainable initiative will help Russell Roof Tiles optimise energy usage and further support its sustainability goals.

Andy Mangena, Customer Success Manager at Intouch Monitoring, added, “It has been an absolute pleasure working with Dan and his team over the past few months to implement our Production Monitoring system into their plant in Burton. I am excited to see the positive impact the system is having on their performance and to witness the measurable improvements in their utilisation and OEE. I also look forward to working with Dan on implementing our new Energy Monitoring module, which I know will assist their business in reducing energy consumption and costs.”

The company started its sustainability journey over 10 years ago. Russell Roof Tiles’ long-term ambition has always been to reduce emissions that damage the environment and improve its operational efficiency while strengthening its wider communities.

Russell Roof Tiles looks forward to getting more data and understanding its overall equipment effectiveness (OEE) footprint. The company remains committed to continuous improvement and innovation as they strive to provide high-quality products and UPVC accessories for top housebuilders and high-profile social housing and commercial projects across the UK. The company produces thousands of tiles every week that are used on roofing across the UK, for all the UK’s premier housebuilders and developers.

Read more news from Intouch here.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email