RNA Design and Manufacture Robotic Loading and Testing System

A customer challenged RNA Automation to design and manufacture a fully automated robotic loading system with minimal operator intervention for the manufacture, test and packaging of a tyre pressure sensor.

The system was required to automatically load components into a vertical moulding machine. Each mould tool (two off mounted to a rotary index table) had four mould impressions which required a total of eight components to each mould tool (four Inserts and four Antenna). On completion of the moulding cycle the four mouldings were automatically removed, the moulding sprue detached and then placed to a cooling carousel. From the cooling carousel, the mouldings are tested, firstly for continuity across the antenna pins and then into a leak decay station. On completion, the finished components are either rejected (if either test is failed) or automatically packed. The packing area included an automated empty box in-feed and fill box out-feed.

RNA drew upon its extensive experience in component handling, testing and robotic transfer to develop this fully automated solution.

Challenge

- The automated system must achieve precise repeatability and positional accuracy when placing the inserts and antennas to the moulding tool.

- The mouldings are at 70°c when removed from the moulding tool; they have to cool before testing. The enervative cooling process facilitates up to a maximum of 12 minutes of cooling time.

- The system must automatically place good mouldings in the appropriate packaging and securely quarantine rejected mouldings for further manual inspection.

Solution

The process flow chart below shows the main functional elements of the solution.

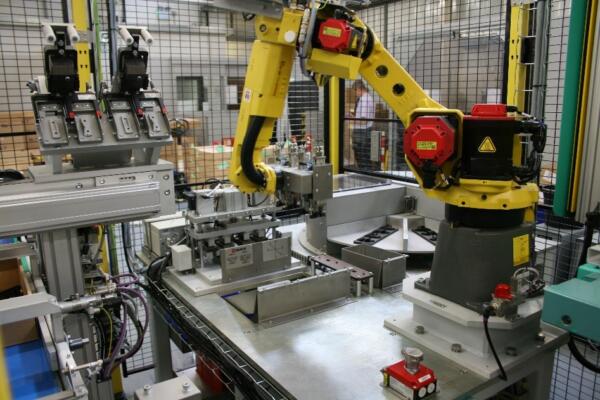

To begin the process, two types of parts (Insert & Antenna) are fed and orientated via two vibratory bowl and linear feed systems. The components are fed to two independent precession shuttle mechanisms so that the Insert and Antenna are always in a known repeatable and accurate position. RNA selected a Fanuc M10iA robot complete with a specifically designed double gripper mechanism to pick four Inserts and four Antenna from their respective locations. The Inserts and Antennas are then placed in the correct orientation within the four-cavity moulding tool. Our client used an Arburg 1200T vertical moulding machine with a two position rotary index table, and this enabled RNA to simultaneously load inserts and antennas while the moulding process is taking place.

On completion, the two-position rotary index table actuates and presents an open mould tool to a second Fanuc M10iA robot. The robot utilising a double gripper picks the four previously moulded components along with the moulding sprue. The robot indexes and drops the sprue material into a recycling bin. The four mouldings are now placed to the continuity test station. If all four mouldings pass, they are then placed within the required cooling area.

One of the critical requirements of this project is that all mouldings go through a decay test cycle. When the mouldings are removed from the mould tool, they are at a temperature of 70°C. To ensure that the efficiency and accuracy of the test process is maintained, it is necessary to reduce the moulding temperature in a controlled manner. RNA developed a cooling system based on a rotary table and cooling fans.

After the cooling phase, the mouldings are placed to the leak decay test station. All four mouldings are detected in the station and they are all marked with a simple pin stamp. The leak decay test is based on 3 bar @0.3cc/min. On completion of the leak decay test, all four components are marked for the second time with the pin stamp. All four mouldings are now removed automatically and placed with a holding device within the packing area. If they fail, they are placed within a second secure quarantine bin.

The packing area consists of an automatic box in-feed and out-feed system along with the escapement mechanism. An empty box is presented and filled with tested mouldings, each box has seventy-two pockets and each pocket holds two mouldings. Once the box is filled, it is automatically released and transferred to the out-feed conveyor system. The capacity of the in-feed and out-feed conveyors is ten boxes.

Key Features & Benefits

- Throughout the process, we use Poka-Yoke design principles for our tooling, location fixtures and grippers.

- The Cooling system improves cooling time and ensures the integrity of the moulding is maintained.

- Continuity and Leak Decay test stations with positive marking of good and bad mouldings.

- Handling processes with extremely high precision and accuracy, multiple sensors monitor part presence at key stations ensuring reliable, repeatable positioning of components.

- A fully integrated, compact system provides considerable savings in labour cost, floor space and WIP.

- Improved productivity, consistent product quality and minimal waste.

- Future proof – the system can be programmed to suit new or additional components.

RNA Automation Skills:

- Machine building and integration

- Machine and Process Control

- Robot System Integration

- Feeding and Handling

- Project Management

RNA Automation Ltd

+44 (0) 121 749 2566

Website

Email