Reshoring of Pet Products a Tail-Wagging Success for Protool Plastics Group

The Protool Plastics Group recently helped relocate the production of EcoPet Recycled’s range of pet products from China to the UK. Protool delivered a complete range of pet products, including design, prototyping, toolmaking and full production in only ten weeks.

The Protool Plastics Group, an injection moulding group based in Fareham and Manchester, manufacture injection moulded components and assemblies for the UK, EU and worldwide markets.

A keen advocate for UK-based manufacturing, Protool’s latest collaboration with pet product brand EcoPet Recycled is a true reshoring success story. Not only are Protool now manufacturing the product range here in the UK, but the company also enlisted help from local product designers and developers and a Midlands-based toolmaker to make the project possible.

Protool Group Managing Director Michael Hadfield said:

“In February 2021, we were approached by a Manchester-based entrepreneur who had, for many years, imported a range of pet products from manufacturers in China. Due to increased costs of transport associated with COVID-19 he found it impossible to meet demand while still using sea-freight to control escalating costs.

“Eli Portnoy of Merton Connect Limited, home of EcoPet Recycled among other brands, was very easy to work with as he knew what products he wanted, how many he wanted and most importantly, what price he needed them for.

“The initial meetings were very simple. I sat with the client and advised the maximum weight the products could be for polymer usage and maximum wall sections and the required amount of tool cavities to achieve the required output to meet the cost.

“Upon agreement of manufacturing costs, we moved forward with Andrew Ives Product Design to produce distinctive component designs and printed prototypes for customer approval.

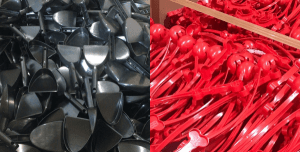

“The client’s main focus was to produce a UK manufactured range of pet products that used as much recycled material as possible and this was largely successful as all scoops and throwers are 100% recycled with only the chew toys have a small percentage of virgin polymer to improve performance.”

The UK element did not stop there, with tooling made in record time by CGP Engineering in Leicester, making this a great success for UK design and manufacturing.

All products are now ready to deliver in volumes from low thousands to hundreds of thousands and enquiries should be made to Merton Connect Limited on 0161 5037722 or via email eli@mertonconnect.com.

The Protool Plastics Group are ready to take your injection moulding enquiries now. For more information, visit www.protoolplast.com or get in touch using the contact details below.

Protool Plastics Group

+44 (0) 1329 822940

Website

Email