Proximity | Smart Manufacturing 101: What Is It, How Do You Get There and Why Should You Care?

You’ve probably heard the term ‘smart manufacturing’ being thrown around by companies like us. If not smart manufacturing, you’ve probably heard its interchangeable term: Industry 4.0. But what does smart manufacturing actually mean? What is it exactly? And how do You get there?

On Wednesday 14th September, experts from the leading manufacturing ERP software, real-time production monitoring, and Manufacturing Execution System (MES) vendor, DELMIAWorks, will host a webinar explaining the 101 of smart manufacturing, plus provide you with some practical steps on how to get started and make your manufacturing floor smarter.

Don’t worry if you cannot attend the live webinar, as every registrant will be sent a recording after the event.

Commenting on the webinar. Tom Grigg, Proximity’s Solutions Architect for DELMIAWorks, said:

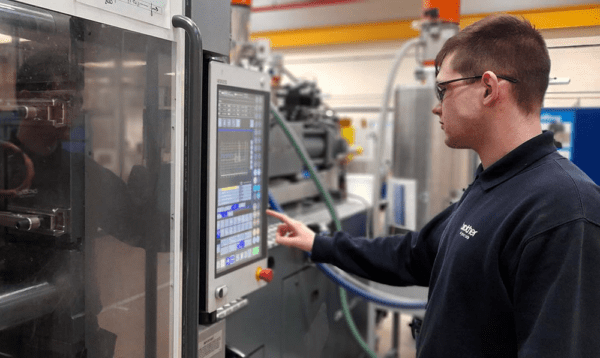

“Automating the shop floor not only builds quality and predictability into the manufacturing environment; it also reduces staff resourcing costs and helps companies compensate for the shortage of skilled manufacturing workers.

“We have noticed that the demand among plastics manufacturers for solutions that deliver the automation and data capture of Industry 4.0 has never been more robust.

“DELMIAWorks’ real-time production, MES, and shop floor automation software is increasingly popular for both existing and prospective customers across the UK, Ireland, and Northern Europe.”

Join Dick Longoria and Ramon Busboom as they simplify these steps and walk through how successful companies are now navigating their transformation journey to be tomorrow’s leaders.

During the webinar, DELMIAWorks will cover these critical topics about intelligent manufacturing:

- How to gather real-time manufacturing floor data

- How to gain visibility of your entire manufacturing operation

- Optimising your production flow and managing work in progress

- How to measure and improve overall equipment effectiveness (OEE)

- How to take control of raw materials, scrap & inventory

- Ad, ultimately, uses real-time data to drive your business forward.

Register now to learn more about navigating and transforming your manufacturing future.

Read more news from Proximity here.