Protool Utilises Polycarbonate Regrind for Lighting & Electronics Projects

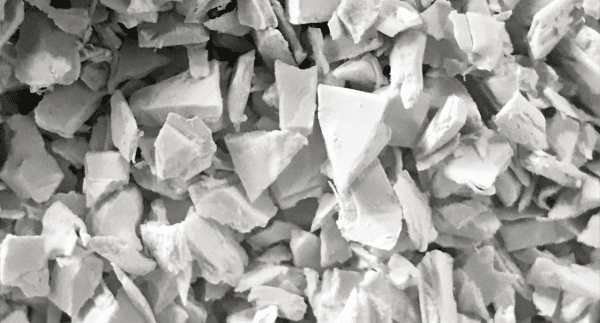

Protool Plastics Group has confirmed that all polycarbonate sprues and scrap is now separated for cleanliness and regrind, resulting in no white or clear polycarbonate being sent to landfill.

Polycarbonate recycling is helping to increase customer accounts for the Fareham and Manchester-based injection moulding group.

The Protool Plastics Group has invested heavily in recycling equipment and contamination-free storage systems to produce high-quality recycled polycarbonate for use on consumer and industrial products.

The operations teams in Fareham and Manchester can now confirm that all post-processed material and reject parts are granulated and reused onsite, meaning that no white or clear polycarbonate is sent to landfill.

Initially aimed at cost-saving and environmental protection for its existing customers, The Protool Plastics Group have expanded this and are looking for new customer outlets for its recycled material.

Group Managing Director Michael Hadfield stated:

“We have focused on polymer recycling for many years, but it is only recently that recycled grades have been accepted in the lighting and electronics sectors.

“As the focus switches to Cradle to Cradle design, companies are becoming more focused on recycled grades of polymers and also accepting the slight differences and minor contamination that is possible when using recycled material.

“The slight negative in appearance is totally offset by the positive circular economy credentials and carbon saving over the use of virgin grades of material.”

Current recycled grades offered by The Protool Plastics Group are polycarbonate (white and black) and polypropylene (natural and black).

The benefits of the circular economy approach are numerous and include:

- Waste reduction

- Greater resource productivity reducing the need for virgin feedstock

- Reducing the environmental impact of our product consumption

The Protool Plastics Group are ready to take your injection moulding enquiries now. For more information, visit www.protoolplast.com or get in touch using the contact details below.

Protool Plastics Group

+44 (0) 1329 822940

Website