Protool Partner Lati to Provide Thermal Analysis Service for Heat Sinks

The replacement of aluminium heat sinks with polymer heat sinks made from thermally conductive plastics for injection moulding is a growing trend for lighting and electronics manufacturers across Europe.

The Protool Plastics Group is at the forefront of this development in the UK where it can bring its project, tooling and injection moulding expertise together to deliver true metal replacement plastic mouldings.

The efficiency of the modern LEDs used by lighting manufacturers is greatly influenced by the temperature achieved during their use, and this in turn is a factor of the power of the LED and the design and material of construction of the heat sink. It is a major part of the design process to identify that the design works together with the material to ensure the interface temperature remains below an acceptable maximum.

Lati has an extensive portfolio of thermally conductive polymer compounds covering a range of different base polymers and a range of different thermal conductivities. It has been active in the European lighting market for many years and supplies thermally conductive compounds for heat sinks used in some market leading applications.

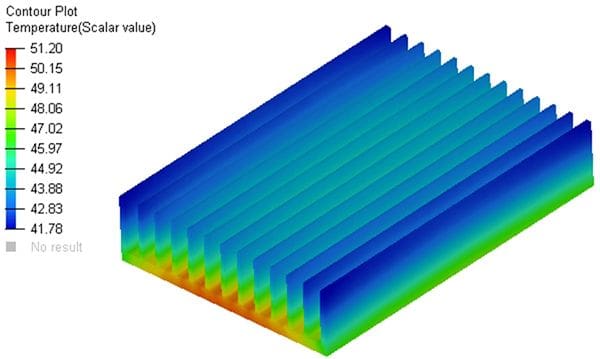

Now Lati and The Protool Plastics Group have teamed up to offer a complete project development service within the UK market including the provision of thermal analysis. This technique operates using the 3D CAD files developed for a mould tool design and utilising Lati’s many years of expertise it is possible to determine the temperature range that the LED interface will reach when running under ambient conditions. This in turn will determine whether the design and material selection are fit for purpose.

Many established heat sink applications are based on LATICONTHER thermally conductive nylon 6 which offers an average thermal conductivity higher than 10 W/mK. Despite the fact that aluminium has a thermal conductivity some 20 times greater, if the lighting assembly is to be used in ambient conditions where there is no significant airflow, then a heat sink from LATICONTHER can be just as effective in ensuring the interface temperature remains below the desired limit. This can be very effectively demonstrated by the thermal analysis in advance of investing and cutting a mould tool.

Group Managing Director, Michael Hadfield, stated “Our Fareham site has manufactured polymer heatsinks for several years and as such has significant experience in the process parameters. We viewed this as a growth market in 2014 and invested in a R&D project to understand how the available materials processed, achievable tolerances, post mould warpage and thermal performance.”

Significant time and money was invested to perfect the processes and tool design and this allowed us to confidently move forward with our first projects in 2015/16. Our extensive experience now make us ready for more complex shapes, sizes and applications.

He further commented “Thermally conductive polymers give much more flexibility to the product designer than aluminium. Complex clips and snap fits can be incorporated and the material can take self-tapping screws without the need for post mould operations, often saving significant amounts of time on final product assembly. The overall cost savings can be significant.”

Andrew Donkin, Lati UK Sales Manager, commented “Polymer heat sinks offer many benefits to lighting manufacturers looking for design flexibility, light-weighting and the cost reductions arising from reduced post moulding operation. Lati is pleased to be teaming up with The Protool Plastics Group to offer the complete service needed to be able to provide a designer or manufacturer with the confidence that a polymer heat sink will be an effective solution.”

Protool Plastics Group

+44 (0) 1329 822940

Website

Email