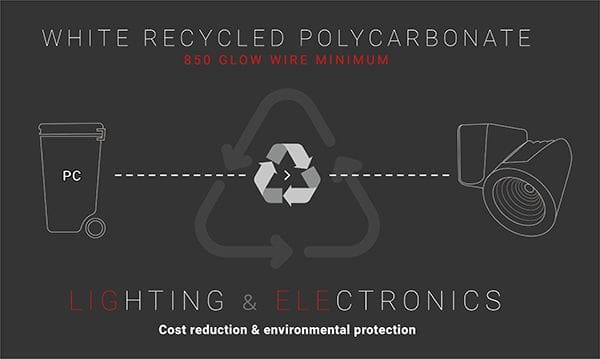

Protool Plastics Launch Recycled PC for Lighting & Electronics

The Protool Plastics Group has invested heavily in recycling equipment to produce high quality recycled polycarbonate for the lighting and electronics sectors with a ‘Circular Economy’ approach.

Although in the early stages we can already certify that no clear, opal or white polycarbonate is removed to landfill from our Protool (Manchester) site, with all waste being granulated and re-compounded for use on new products. We aim to achieve this in our Fareham facility by the middle of 2019.

The project which is being headed in Manchester by Operations Director Ian Hunter takes sprues, reject parts, recycled lighting and electronic components and via our granulation and re-compounding process produces standard 25Kg bags of high-quality polymer for use in our moulding facilities.

Initially aimed at cost saving and environmental protection for our existing customers The Protool Plastics Group are now ready to offer this to new customers across the UK and Europe.

Group Managing Director Michael Hadfield stated “We have supplied major lighting and electronics companies for many years and began discussions last year on how we could offer a circular economy approach to the industry. This started a six-month project of investment and operational integration to a point where we are now successfully supplying 100% recycled components into some of the World’s biggest lighting brands.”

The polymer feedstock is all from 850 & 960 glow wire clear, opal and white (RAL9003, RAL9010 & RAL9016) polycarbonate producing a very clean non RAL specific white blend.

Michael Hadfield continued “The polymer being a mix of whites is ideal for internal and painted parts where a specific external colour is not important. Not only does it offer a cost reduction on virgin polymer it also adds to the recycled component approach that is rightly at the forefront of product designers’ minds across the UK. The Protool Plastics Group intends to focus on recycled materials wherever possible and will be adding other polymers to our recycled portfolio in the near future.”

Current recycled grades offered by The Protool Plastics Group are PC (white and black) & PP (natural and black).

The benefits of the Circular Economy approach are numerous and include:

- Waste reduction.

- Greater resource productivity reducing the need for virgin feedstock.

- Reducing the environmental impact of our product consumption.

The Protool Plastics Group (Fareham & Manchester) are ready to take your injection moulding enquiries now on the below:

Protool Plastics Group

+44 (0) 1329 822940

Website

Email