precisionMixhead From KraussMaffei: Smaller Size, Higher Performance and Outstanding Ease of Service

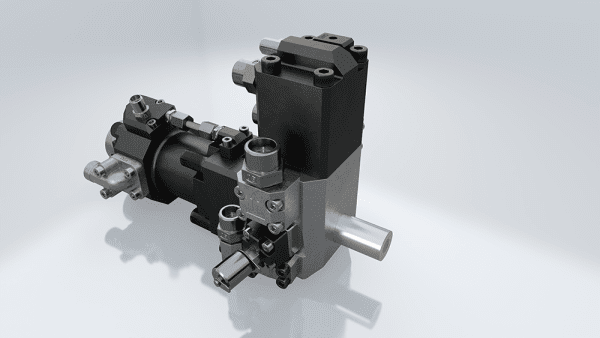

KraussMaffei is introducing a new generation of high-pressure mixing heads, called the precisionMixhead, for processing polyurethane at the K trade show.

“With its smaller size, higher performance and outstanding ease of service, the precisionMixhead sets new standards in its class,” says Prof. Jens Liebhold, Head of Plastification Technology and Mixing Heads. “The new design pairs maximum precision in mixing quality with maximum availability for the production process.”

Small is beautiful and saves energy

The precisionMixhead features ideal dimensions. Compared to its predecessors, the compact design offers a volume savings of up to 25%. This makes the new mixing head easier to integrate into complex molds.

The weight has been reduced also. With a total weight of about 10.5 kg, the new precisionMixhead 8/12 is about one-fifth lighter than its predecessors. This saves energy because the handling robot has less mass to move.

The smaller, more lightweight mixing head is also faster and easier to move during manual handling and maintenance work. This saves time and increases productivity.

Excellent part quality

KraussMaffei mixing heads are market leaders thanks to their high mixing quality. By using state-of-the-art calculation methods for flow simulation, an additional performance boost has been given to the precisionMixhead. This made it possible to enlarge the process window by up to 30% especially for materials that are difficult to mix. This reduces the risk in the production process and minimizes the scrap rate even when the requirements are complex. For the user, this means more good parts, less scrap.

Replacement parts for fast service

Mixing heads require regular maintenance to produce at a consistent performance capacity. To attain maximum availability in this respect, the wear-prone parts in particular are designed for quick replacement. In addition, a global service concept ensures that repairs are as fast as possible under conditions that are fair and transparent. Customers are also pleased by the fact that the high availability means they do not have to invest as much in backup solutions.

Read more news from KraussMaffei here.