Positive Start to 2019 for Colourmaster NIP

Following a good year in 2018 for Colourmaster NIP, 2019 is promising to be even stronger following the addition of several exciting new products in recent months. These complement the Clariant Omnicolor® masterbatch range and plastic raw materials for which Colourmaster are well known.

IR detectable black masterbatch from Clariant, biodegradable plastic additive from BioSphere, glow in the dark compounds from Clariant and injection mould tooling are amongst the new products on offer.

IR detectable CESA®-IR Black masterbatches have been developed to make identification of polymers during the recycling process possible, which is not the case with traditional black masterbatches. The traditionally used carbon black has been replaced in CESA®-IR masterbatches with colourants which allow the polymer type to be easily identified using current detection methods. This means they can be easily sorted into polymer type and directed into the correct stream for proper recycling to take place, which is currently not the case.

BioSphere biodegradable plastic additive is a unique, easy to use, additive package which rapidly enhances the ability of plastic to biodegrade when added to a polymer. With as little as a 1% addition of the masterbatch, degradation is speeded up by 100-200 times when compared to plastics without the additive. BioSphere works by allowing acids, secreted naturally by microbes, to soften the macromolecules within plastic. These microbes are then able to consume the macromolecules much more quickly, resulting in much faster biodegradation occurring. What is left behind are the “normal” products associated with biodegradation i.e. CH4, CO2, biomass, and water.

Glow in the dark CESA®-lux compounds, based on a PP carrier system, contain phosphorescent pigments. They work by accumulating energy when the component is exposed to a light source which is then emitted when dark, giving an afterglow effect. The effect can last for hours and the activation/deactivation process is ongoing and repeatable. The afterglow brightness achievable is determined by the proportion of afterglow crystals in the compound and the intensity of activation energy.

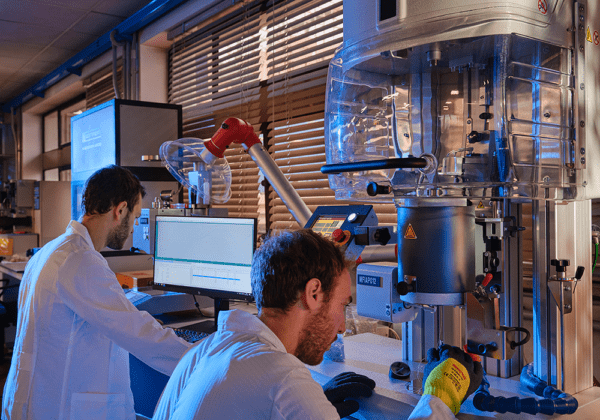

Injection mould tooling has also been recently added to the Colourmaster NIP portfolio. Manufactured in the UK by their toolmaking partner, the tooling is of high quality, competitively priced and produced to an agreed specification and lead time, using state of the art technology. Full functional testing of the tool prior to delivery and first off sampling, if required, are offered at no additional cost along with any adjustments required.

For details on these or any of the products supplied by Colourmaster NIP contact them on 0161 624 2114, visit their website www.colourmaster.co.uk or email sales@colourmaster.co.uk.

Colourmaster NIP

0161 624 2114 / 0161 624 9479

Website

Email