Polymer Compounders Introduces Notoxicom® Product Family

Polymer Compounders Limited (PCL) is proud to announce an entirely new category of product that will redefine flame retardant polymers. After many years of complex research and development, Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000 (FR PC/ASA) have now been launched.

Why Notoxicom?

Notoxicom® is PCL’s registered tradename for specialist halogen and aryl ester-free flame retardant polymers. These materials are unique because they retain industry-leading performance and are much less toxic. PCL has polymers to suit many applications within this range, from battery casings to state-of-the-art medical devices.

Over time it is expected that the Notoxicom® family of products will grow further to support the innovation of PCL customers.

Stephen Blair, Technical Manager at PCL, defines it as “world’s first UL94 V0 at 0.8 mm halogen and aryl phosphate ester free, very low toxicity FR PC/ABS and FR PC/ASA materials that do not compromise on material properties and give lightweighting advantages.”

Background

As the world around us is changing, so are our polymer needs; more eco-friendly conscientious and safer choices are being made by consumers daily around the globe.

With the addition of the standard flame retardants in Engineering Styrenics and their blends such as TBBA and RDP/BPA-DP to the European Chemical Agency (ECHA) CORAP (community rolling action plan) list, PCL knew something needed to happen about the types of additives used in all significant flame retardant applications. Understanding the significance of the upcoming ECHA review and the consequence of a shift in the industry made sense for PCL to develop its new patented polymer and help facilitate a positive change to safer flame retardant materials for the reasons outlined by the ECHA.

With a combined knowledge and experience of over 50 years of polymer science, PCL accomplished the development of not one but two non-halogenated flame retardant materials. The materials are Notoxicom® B6000 – an FRPC/ABS Blend and Notoxicom® S6000 – an FR PC/ASA blend.

Both Notoxicom® B6000 and Notoxicom® S6000 materials are not only safer and better overall for the environment but are also much better at carrying out the job required of any halogenated and aryl phosphate ester-based flame-retardant polymer. Lastly and most importantly, they are compliant with the ECHA.

How were these objectives achieved, and what are the key innovations?

The first key innovation centred around the fact that traditionally when you add an additive or flame-retardant package to a material, you ultimately sacrifice performance in another area such as heat performance or strength.

This means the polymer could end up with a lower impact strength and a lower tolerance to heat. Simply put, traditional flame retardant materials cannot stand up to the rigours of the moulding process for an extended time. Halogenated flame retardancy packages are not bound within the polymer matrix. Due to this, the additives, in turn, react or start the migration process in the injection moulding barrel if the residence time is too long. Another weakness of traditional flame-retardant packages is that the final moulded component will have lower stiffness at elevated temperatures because the flame-retardant package has a plasticising effect on the host polymer. In addition, standard FR/ABS materials that also contain halogens utilise additional toxic chemicals such as Antimony Trioxide as a co synergist to generate the compound, which in turn extinguishes the flame.

Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000 (FR PC/ASA), on the other hand, maintain their properties in all areas, which enable them to be utilised in many applications. They achieve this by not separating the flame retardancy from the polymer at the molecular level, essentially acting as one, with nothing leaching out.

What is unique about this technology development, and what are its implications?

PCL’s technological development has ultimately proved that the use of halogens or liquid phase materials are not necessary when creating a superior flame retardant polymer. It has also shown that products such as Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000 (FR PC/ASA) surpass all the required technical aspects of a flame retardant in a much safer way.

PCL has been working closely for many months during the formula development stage of the products, with an industry-leading test house for all results.

What were the key objectives of this material development?

Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000’s (FR PC/ASA) properties’ can be broken down and summarised into the following:

- To be a material with a halogen-free classification, which also has a favourable toxicity profile when compared with all other halogenated flame-retardant materials and liquid non-halogenated flame-retardant materials.

- A material that does not migrate from host plastic.

- A material that does not ‘bioaccumulate’.

- A better melt-processable material.

- Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000 (FR PC/ASA) also maintain their physical properties and attributes in all areas compared with halogenated and liquid non-halogenated flame-retardant materials.

- Patented and manufactured in the UK at PCL’s Durham manufacturing site with short lead times.

Notoxicom® B6000 (FR PC/ABS) – Technical Data

- High flow and excellent complex tooling processability.

- Good heat performance Vicat (B/50) – 125°.

- Excellent Impact performance – 46 kJ/m2.

- Halogen-Free UL94 V0 rating at 0.75mm.

- GWEPT at 960°C

- 5% lower density (Sg of 1.14g/cm3) compared to similar FR PC/ABS materials.

- Visit https://bit.ly/b6000-datasheet_pcuk to view the full ISO 9001:2015 datasheet for Notoxicom® B6000.

Notoxicom® B6000 (FR PC/ABS), is the slightly tougher of the two products with an impact of 46 kJ/m2 would be an excellent choice for highly specialised automotive applications such as EV battery casings or applications that require toughness, with exceptional flame retardancy.

Watch the video below to see a Mouldex representation of PCL’s Notoxicom® B6000 in action.

Comparative Sustainability and Recycling robustness of leading FR PC/ABS materials

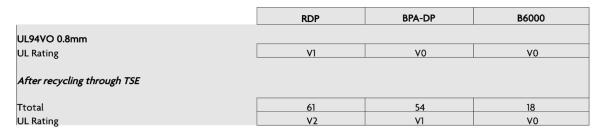

Notoxicom® B6000 has superior property retention after recycling compared with other FR PC/ABS grades. The graph below demonstrates that after repeated processing, Notoxicom® B6000 retains all its flame retardant properties. Traditionally materials like FR PC/ABS are unable to be reprocessed for fear of the flame package leaving the material. This is due to the ingredients’ co-existing’ as opposed to being a ‘unified’ bound polymer matrix like Notoxicom® with its patented formula.

Notoxicom Recycling Robustness

Notoxicom® S6000 (FR PC/ASA) – Technical Data

- Excellent UV stability.

- High flow and excellent complex tooling processability.

- Good heat performance Vicat (B/50) – 125°C.

- Excellent Impact performance –15 kJ/m2.

- Halogen-Free UL94 V0 rating at 0.75mm.

- GWEPT at 960°C.

- 5% lower density (SG of 1.14g/cm3) compared to similar FR PC/ASA materials.

- Visit https://bit.ly/s6000_datasheet_pcuk to view the full ISO 9001:2015 datasheet for Notoxicom® S6000.

Notoxicom® S6000 (FR PC/ASA), with its great weathering capabilities, is an excellent choice for any outdoor application that also requires class-leading flame retardancy.

PCL’s intention and persistence from the beginning to keep key performance attributes has meant that both halogen and aryl phosphate ester free flame retardant’s Notoxicom® B6000 (FR PC/ABS) and Notoxicom® S6000 (FR PC/ASA) have a market-leading balance of flow, impact, high-temperature performance and processability. Furthermore, and most importantly, both materials do not contain any toxic halogens or aryl phosphate ester, enabling a safer world for everyone.

Flame Retardants and Key Precursor; Yellow Phosphorus (YP)

Within the world economy, China manufactures and supplies more than 70% of the world’s supply of Yellow Phosphorus (YP). In recent times due to growing pressure from the different economic nations to move toward a greener solution for a greener, healthier planet, China has decided to shut down a significant capacity of its ‘coal-powered manufacturing plants, which make the ‘Yellow Phosphorus’ precursor. As a result, the world’s supply of this key product has dropped significantly. China accounts for 70% of the world’s production of YP. China took this action to help clean up the environment and have further imposed a 90% reduction in YP production at some significant producers.

What effect has this had on the polymer market?

This chain of events is being felt across both the manufacturing and polymer industries, pushing the prices of certain materials higher than they have ever been. Additionally, all primary FR ABS materials and FR PC ABS materials rely on this precursor almost in their entirety. Manufacturers of these products require large amounts of RDP and BDP from producers. PCL is not suggesting that Notoxicom® is entirely immune to this issue but is pleased to say that its superior flame retardant product range Notoxicom® is readily available; despite all that is going on in these precarious times. Several factors contribute to this, but PCL’s crucial innovation within the product has made this so by utilising new technologies.

Notoxicom® in addition to everything mentioned above, the Notoxicom® family of products have an underlying formula that enables them to meet GreenScreen® level 3 requirements. GreenScreen® is one of the most recognised methods of comparative chemical hazard assessments available. Benchmark Scores provide a standardised and straightforward way to compare and communicate about chemical hazards. More information on what GreenScreen® is all about; can be found here.

To learn more about the Notoxicom® family of products, click here, or visit https://bit.ly/notoxicom_technical_information_pcuk.

In addition to Notoxicom® B6000 and Notoxicom® S6000, PCL has added two new products to the Notoxicom® family. They are as follows:

Notoxicom® B6303

This material is an enhanced heat deformation, 1.5 mm V0 rated flame retardant ABS blend. It can be used in both extrusion and injection moulding applications. More information is available here: https://bit.ly/notoxicom_B6303_datasheet_pcuk. Notoxicom® B6303 has been formulated to be tailored more around extrusion applications; however, it can also be able to be used in most injection moulding applications.

Notoxicom® A6000

This material is an Injection moulding grade of a non-halogenated PC blend with exceptionally low smoke toxicity and flame retardancy, suitable for transport applications. More information is available here: https://bit.ly/notoxicom_A6000_datasheet_pcuk. Notoxicom® A6000 has been formulated to be tailored more around transport applications with its exceptionally low smoke toxicity.

For more information on the Notoxicom® product family, visit polymer-compounders.com, or use the contact details listed below to get in touch with the PCL team.