Plunkett Associates Brings Production Home for TRT Lighting

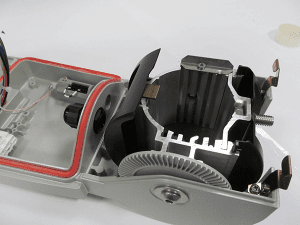

If reshoring your tool is not a viable solution, a new UK-manufactured tool could be the answer instead, which is what Plunkett Associates client TRT Lighting recently opted for. Benefits included a shorter and more responsive supply chain and supporting global sustainability.

TRT Lighting designs, manufactures and supplies energy-efficient, environmentally friendly performance lighting products for the road, tunnel and exterior lighting markets.

As a long-standing supplier of parts and prototypes into TRT through both UK and Far Eastern suppliers for many years, Plunkett continually explores alternative options to see if there are better ways to manufacture parts. With a constantly evolving marketplace driven by technological advances, global economics and, of course, COVID, costs can fluctuate significantly.

UK tooling and moulding capacity

The advantages to the client were indisputable, with a dramatic reduction in component ‘miles’, a shorter, more responsive supply chain, and a reduction to the vagaries of exchange rates.

As a result, earlier this year, a new steel production tool was manufactured in the UK.

Advantages of being made in Britain

With the work being carried out in-house, TRT could be kept informed of progress every step of the way and with T1’s signed off soon after the tool was made, production could commence.

TRT has been delighted with the results as Rob Waters, Technical Director at TRT Lighting, says:

“Having a proactive supply chain partner actively looking to help improve both the quality of product and the services provided is a breath of fresh air. We consistently receive professional service and high-quality products from Plunkett’s, no matter how big or small the job is!”

Supporting global sustainability

The advantage of having a local manufacturer, easy communication, and the potential to hold stock to be called off whenever required all cited as benefits; this is even before factoring in the enormously reduced shipping distances that helps to support global sustainability, a key feature of the client’s mission statement.

If you’re considering a UK manufacturing option, visit www.plunkettassociates.co.uk for more information or use the contact details listed below to get in touch with the team at Plunkett Associates.