Plunkett Associates Increases CNC Machining Capabilities

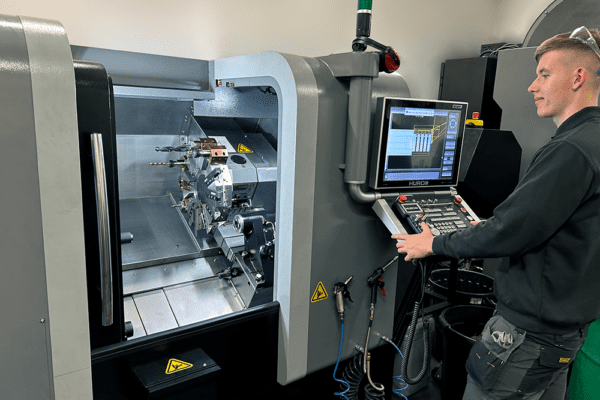

Plunkett Associates, specialists in low volume and prototype manufacturing and tooling, has detailed its new CNC machining capabilities as its toolroom expands.

Plunkett Associates continually strives to provide clients with the highest quality service for all manufacturing needs. We must ensure that clients’ expectations are being exceeded wherever possible.

Responsive to client enquiries

We endeavour to achieve this through the management of our supplier network, including our sister company, Adept Precision. This enables us to be reactive to client enquiries and actively responsive in getting parts made quickly.

Attention to Detail

Our 3-axis machines are ideally suited to prototype and low volume batch work, but the attention to detail is what really makes us stand out. With a wide range of capabilities, we are happy to tackle complex parts as well as tooling in most grades of aluminium.

The 4-axis machines have the added advantage of allowing us to speed up the process as we avoid the need to manually reset the machine. With the assistance of our cobot, we can run lights out shifts and support much higher production quantities.

Why do we Machine in Aluminium?

- Aluminium is a very light metal with a weight of about a third that of steel. Its strength can be adapted by modifying the composition of its alloys.

Aluminium naturally generates a protective oxide coating and therefore is highly corrosion resistant. Different types of surface treatment, such as anodising, painting or lacquering, can help to improve this.

- Aluminium is an excellent heat and electricity conductor.

- Aluminium is a good reflector of light as well as heat.

- Aluminium is ductile and has a low melting point and density.

- Aluminium is 100% recyclable with no downgrading of its qualities.

….and it’s beautiful to machine!

With the capability to machine at up to 24,000rpm and cutters down to 0.3mm diameter, good quality surface finishes and tolerances are achievable; part sizes up to 980 x 480 x 300 can be easily achieved.

Servicing all industry sectors

Whilst many companies talk of the industries they serve, we will tackle almost anything. Although we hold ISO 9001:2015, it should be noted that we do not hold some of the more specific industry accreditations for just this reason. Unlike many companies, we are not just interested in what we can machine ourselves but have established a network of associates that dramatically increases the scope and capacity that we can offer.

Quantities of 1 to 100,000

Quantities range from one-off prototypes to 100,000 plus in a wide range of materials, both plastics and metals. When the process is not an ideal match, we have access straight into a host of other options, from 3D printing to injection moulding.

If you have a requirement, it’s well worth giving us a call – we know just the people to turn to!

Aluminium naturally generates a protective oxide coating and therefore is highly corrosion resistant. Different types of surface treatment, such as anodising, painting or lacquering, can help to improve this.

Aluminium naturally generates a protective oxide coating and therefore is highly corrosion resistant. Different types of surface treatment, such as anodising, painting or lacquering, can help to improve this.