PlastikCity on Tour – PL Machinery

|

Getting your Trinity Audio player ready...

|

(Jess Clarke, Dave Sams, Neal Northwood- Pictured above left to right)

Our next stop was Bedfordshire, where we met with Neal Northwood and Dave Sams of PL Machinery, a well-established supplier and service provider of ancillary equipment for the plastics processing industry. Situated in this picturesque county, PL Machinery stands out as a shining example of expertise and reliability, serving the plastics sector with dedication and skill.

PL Machinery was founded in 2006 by Dave Sams and Neal Northwood, both seasoned experts with decades of experience in the plastic processing industry. The company’s roots are deeply embedded in servicing and maintaining the equipment they supply, a focus that continues to be a cornerstone of their operations today.

The company offers a wide range of high-quality ancillary equipment from leading brands such as Main Tech, Conair, Adler, Boe-Therm & ST Machinery. Their product portfolio includes granulators, shredders, temperature control units, chillers, conveyors, material storage, material handling equipment, among others. This extensive range ensures they can meet the diverse needs of their customers, providing tailored solutions for every application. The team’s in-depth processing knowledge enables them to specify and provide their customers with the right solution for their specific mould shop.

When Dave and Neal decided to establish PL Machinery, they brought with them a wealth of knowledge and a clear vision. Previously, both had worked at PL Plastics, which was the largest supplier of ancillary equipment in the UK. This experience laid a solid foundation for their new venture, allowing them to build a company that prioritises service and support.

Initially, PL Machinery started small, focusing on servicing and supporting the equipment they provided. This approach proved successful, and over the years, the company has grown steadily. Today, they boast a skilled team that includes engineers, sales personnel, and administrative staff, all working together to deliver exceptional service to their customers.

A significant part of PL Machinery’s business involves the maintenance and servicing of the equipment they supply. Dave and Neal believe that their extensive experience in this area sets them apart from their competitors. They emphasise the importance of understanding the specific challenges faced by their customers and using this knowledge to offer solutions that are both effective and reliable.

These solutions also extend to pre-owned ancillary equipment. Their broad, in-depth knowledge and well equipped spare parts stock also enables them to refurbish this equipment to re-sell. Again, this provides another option for PL Machinery’s customers, demonstrating that their solutions are truly tailored to the customer’s needs.

Their team includes field service engineers who are qualified electricians and experienced fitters. These engineers are capable of handling a wide range of tasks, from mechanical assembly to electronics and software troubleshooting. Importantly, many of them come from the plastics industry, giving them a deep understanding of the processes and requirements involved.

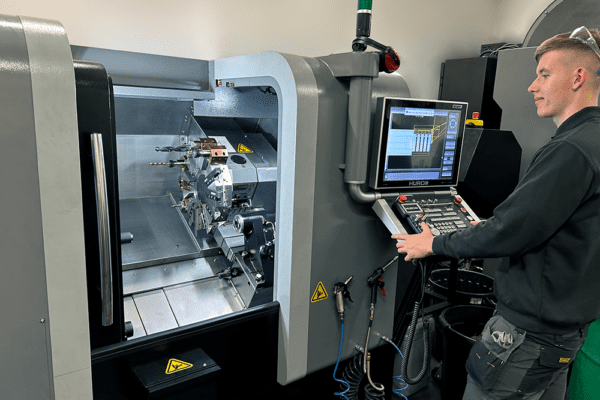

PL Machinery operates from a facility that has been their home for nearly two decades. This building, which was once part of an old airfield, provides ample space for their operations, including office areas and workshop spaces. The location also offers convenient access to major transport routes, facilitating efficient service delivery

The facility also houses thousands of spare parts for a wide range of equipment they’ve previously sold, as well as their current range. This equips them perfectly to deal with any issues which arise with ancillaries they’ve installed, which is a necessary peace of mind for their customers.

In addition to their strong focus on service and support, PL Machinery is also committed to providing high-quality products. They represent reputable brands known for their durability and reliability. For instance, their range of temperature control units from Boe-Therm and gravimetric dosing systems from DigiColor are highly regarded in the industry.

PL Machinery’s approach to business is characterised by integrity and a strong emphasis on customer satisfaction. They believe in doing things right the first time and are not afraid to go the extra mile to ensure their clients are happy with the solutions provided. This commitment to quality and customer service has helped them build a solid reputation in the industry.

As we toured their facility and spoke with the team, it was clear that PL Machinery is a company built on a foundation of expertise and dedication. Their focus on service, combined with their extensive product range and industry knowledge, makes them a valuable partner for any business in the plastics processing sector.

After the tour, we sat down with founders Dave Sams and Neal Northwood to learn more about their journey, the company’s offerings, and their future plans…

Can you tell us a bit about the history of PL Machinery?

Dave: “We were founded 18 years ago, in 2006 – we started trading on April 1st. Neal and I both came from PL Plastics, which was by far the largest supplier of ancillary equipment in the UK at the time. When we started on our own, we initially focused on service and support because that’s what we did at PL Plastics. We were a fledgling company then!”

Neal: “Yes, we were, and still are, the sole owners and directors. We didn’t necessarily need the pressure of having to stand on a podium and say we were going to do millions in turnover. It was about building a solid foundation.”

What sets PL Machinery apart from its competitors?

Neal: “We always say we don’t sell equipment; we sell solutions. If we do sell a dryer or a material handling system and it underperforms, we will put it right at our own cost. We’ve never had that happen, but this approach probably does lose us the occasional order. Overall, it stands us in good stead. We’re not greedy, and we don’t muck stuff up.”

Dave: “Our focus is very much on long-term relationships. We tend to get our orders because we’ve got long-term relationships with people, and they learn to trust us. We don’t have a big team of salesmen pushing for every sale. Instead, we work closely with our clients to ensure they get exactly what they need, not just what’s on offer.”

How many employees do you currently have?

Neal: “We have a small, dedicated team. There’s one salesperson in the north, I cover the south and digital enquiries, and we have two field service engineers. Sue handles all our admin, and she’s excellent at her job. Mick is our spare parts manager, and Ian is our workshop engineer. We also use a contractor for material handling system installations.”

What are your key products and services?

Dave: “We still consider ourselves an equipment sales company, but servicing and maintenance play a massive role in our business. In terms of equipment supply, we represent brands like Conair Auxiliary Equipment , Adler for granulators and shredders, ST Conveyors and Separators, Boe-Therm temperature control units, DigiColor gravimetric dosing systems, Holzer collection systems, and Main Tech Ancillary Equipment.”

Neal: “Our experience in servicing and maintaining equipment allows us to overhaul ancillaries too – we’re very well-equipped to refurbish this equipment in our workshop here in Bedfordshire. This provides another excellent option for our customers.”

What’s your target market?

Neal: “While our core market is plastics, we do extend into other areas. For instance, our granulators and shredders are used in recycling, and we’re starting a relationship with Loma Systems for metal detection and product inspection systems, which will take us into various other industry sectors. The mould heaters we supply are also used for various applications outside plastics, such as in chocolate and food processing. And likewise our range of conveyors and modular workbenches are used in many different production and assembly environments.”

What plans do you have for the next 12 months?

Dave: “We’re looking to expand our team and hire new engineers. We’re also considering participating in exhibitions like Interplas and K Show. We’re looking forward K next year – this is always a great trip where we can spend time with contacts from all of our brands.

“Additionally, we’re working on new product lines, including cube dicers and pelletizers, and have started refreshing our partnership with ST Machinery to include more products.”

Neal: “As we just mentioned, we’re also in the process of finalising an arrangement with Loma Systems, which will definitely be a significant development for us. Loma is a market leader for in-line metal detection and product inspection systems, so this is a really exciting development for us. As a small team, we rely on our reputation, so keeping our clients informed about what we’re doing is crucial.”

Do you have an official company philosophy or mantra?

Dave: “Our tagline is, ‘Whatever your ancillary needs, we have the solution.’ It’s about integrity and the personal touch. We don’t have massive overheads forcing us to chase every sale, and that allows us to focus on quality and reliability, and specifying a solution that works for the customer’s individual process and set-up.”

Neal: “We aim to provide the best solutions and maintain long-term relationships. Our engineers come from the plastics industry, so they understand our customers’ needs deeply. This is essential for our business. This knowledge and our commitment to doing things right set us apart.”

It’s clear that PL Machinery is built on a foundation of trust, expertise, and a genuine commitment to their clients. With their extensive experience and dedication to quality, Dave and Neal continue to steer PL Machinery towards a future of growth and success.

Thank you to Dave, Neal, and the PL Machinery team for their time and insights. If you’re looking for reliable ancillary equipment and exceptional service, PL Machinery is a name you can trust.

Look out for the next edition of ‘PlastikCity on Tour’ to learn more about our excellent UK-based partners.

Find previous ‘PlastikCity on Tour’ posts here.

PL Machinery

+44 (0) 1582 883666

Website

Email