InTouch Monitoring | Plastics Manufacturing in a Volatile World | Blog

As the old saying goes, “when it rains, it pours.” And for plastics manufacturers, these words have been particularly true in recent years. The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating uncertainty in a volatile world.

As humans, we are usually reluctant to change the way we work unless change is forced upon us. Often it takes a crisis to compel us to adapt and make systems stronger and more efficient. Covid-19 has accelerated the shift towards digitalisation, working remotely and flexibly and rethinking supply chains. Manufacturers that are thriving in this volatile world are those that have adapted and innovated rather than stuck to their old ways of working.

In this article, we discuss the unique set of ongoing challenges that plastics manufacturers face and provide effective tips to help overcome them in order to move the dial from survive to thrive.

1. Supply Chain Challenges:

The plastics industry, like so many other industries, has been greatly impacted by the lack of availability of raw materials, which is compounded by delivery delays. Suppliers themselves are struggling to maintain capacity, which creates more disruptions in getting the required inputs to manufacturers. And it doesn’t look like it’s going to improve anytime soon.

China’s zero Covid tolerance, the war in Europe and the ongoing Brexit issues are severely affecting the supply, reliability and transportation of resin. The impact of climate change means organisations need to improve their corporate social responsibility (CSR) and green credentials, which adds additional layers of complexity to overcome.

Plastics manufacturing relies on a global supply chain and given the myriad of challenges, it can be a daunting task to know where to focus to mitigate risk and vulnerability whilst maintaining the best ROI.

This requires a change of thinking in terms of the reliability and effectiveness of global and single-source supply chains.

It’s not a quick fix, however here are some things you can do to build resilience and reduce risk with your supply chain:

- Vet your suppliers thoroughly – you can never do too much due diligence

- Plan for the worst, with effective crisis planning. The pandemic has shown us we can’t always know what’s around the corner

- Don’t rely on a single supplier, wherever possible

- Step away from JIT (just in time) and carry a larger stock of material, which will obviously affect cash flow in the short-term

- Continuously monitor the political and economic climate

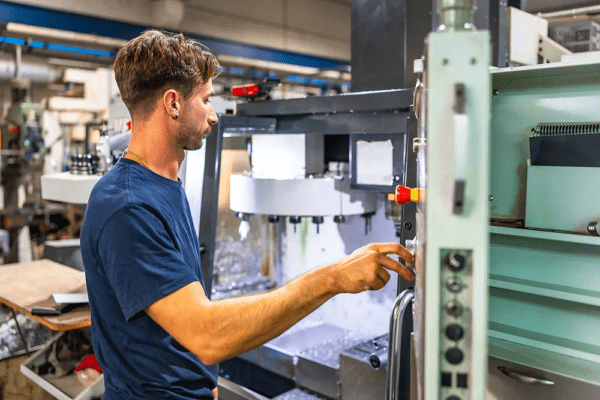

2. Struggling to keep up with production demands is a key sign you are ready to digitise your factory:

Sometimes increasing production does mean having to buy new equipment or hiring more staff but more often than not, manufacturers can get between 6-30% more productivity from their existing resources just by digitising their factory.

Investing in larger premises, new equipment and finding more staff is costly and time-consuming. But turning down business due to lack of capacity isn’t what most businesses would prefer to do, after all the hard work and investment to bring in new business.

So if you’re struggling to accept new orders or get your orders out in time and you aren’t ready to increase your resources, then investing in production monitoring software can instantly increase your capacity. You can achieve more with less (or use your existing resources).

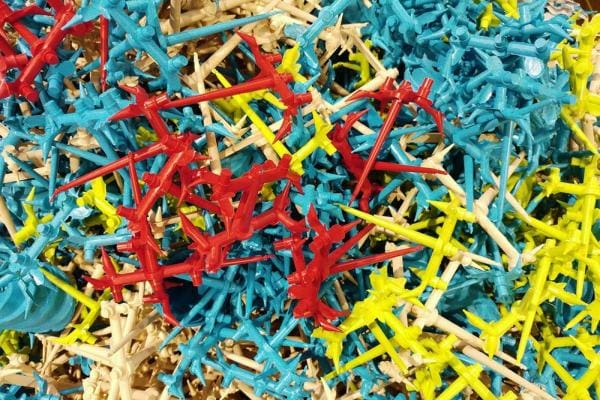

3. If you wish to reduce costs and increase efficiency this is the third sign you are ready to digitise your factory

Costs of material, rent, energy, and labour are all spiralling, and that doesn’t look like changing any time soon. It has never been more important to ensure that you are not wasting any of it but it is very easy to waste significant amounts when there are so many moving parts to a factory. What seems like ‘little wastes’ multiplied by a lot soon add up so a significant amount of lost profit and margins.

There are lots of ways that digitisation can reduce costs and increase efficiency, but here are some examples:

- Having a clear and accessible digital production plan alerts the job setters to have the machine ready for when production is ready to start. One customer improved changeover times by 10-30% which considering they have over 170 changes a week has had a significant positive impact.

- Reducing scrap by pinpointing the actual reasons for scrap and working to resolve it – our customers reduce their scrap significantly. Without a reliable record that highlights the issue, it is impossible to know what is causing the scrap and how to fix it.

- Setting up a tool that is running for example 20 seconds too slowly because someone forgot to adjust the robot’s speed can mean you lose 20% of the expected production for that day. With digitisation, managers can easily pinpoint the reason behind the slow speed cycle and make sure it doesn’t happen again.

- Energy loss. Leaving machines on when they’re not being used is a needless energy drain. Alarms that alert staff when machines have been left on prompt them to switch them off.

- Take your plastics manufacturing to the next level

If you’re experiencing any of the above issues, it’s time to invest in smart technology.

Smart technology can help resolve production bottlenecks, keep up with production demands, and reduce costs.

If you’d like help digitising your manufacturing operations or assistance in improving efficiency and productivity, please get in touch.

Read more news from Intouch here.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email