Plastics Live: The Forum to Assess Manufacturing Alternatives for Plastics Production

Plastics Live, taking place from July 5-6, will explore the alternatives that exist today for the production of plastic parts and is the ideal place to assess conventional production technology and additive manufacturing.

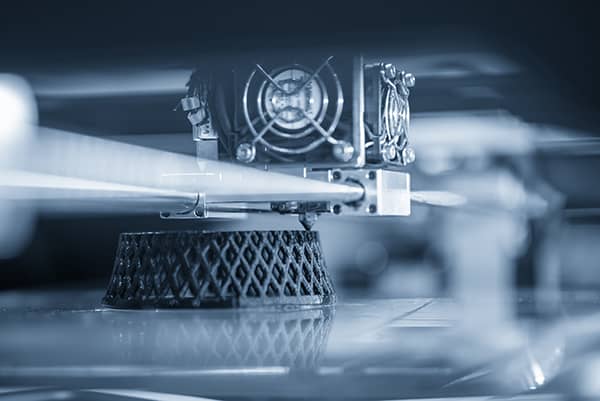

As additive manufacturing (AM)/3D printing continues to evolve, many of the pre-conceptions concerning its usefulness as a production technology for plastic parts and components need to be revisited.

Now an established technology set with a 30-year plus pedigree in the industry, 3D printing is no longer just a solution for rapid prototyping applications.

Today, many 3D printing processes co-exist alongside traditional plastic manufacturing processes as a viable alternative where it can rival them in terms of cost and lead times. For a growing number of applications, 3D printing for batch production offers clear economic and added-value advantages — acting as a spur to innovation and enabling the production of end-use products impossible or uneconomical to produce with the use of alternative methods.

At Plastics Live (incorporating AMPLAS), attendees will be able to see an array of traditional and additive manufacturing (AM) production processes accessible through technology or service suppliers. Today, there is a very real place for AM to reside in a modern production facility as a complementary technology alongside legacy technologies.

John Jones, Event Manager, said: “Broadly speaking, when manufacturers look to produce in plastic, there are many alternatives to consider.

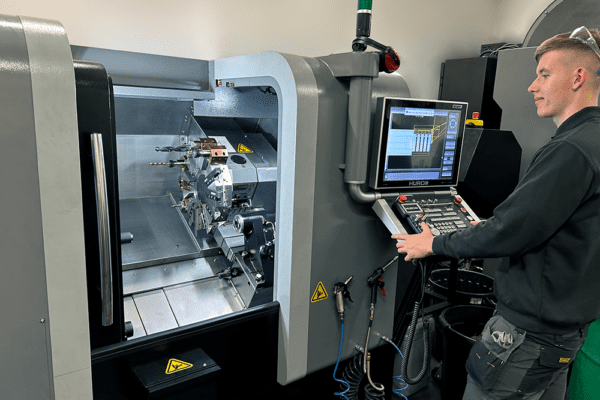

“Traditional manufacturing routes typically include injection moulding, CNC machining or vacuum casting. Manufacturers that do not bring the SLS 3D printing process into the frame at this point are potentially doing themselves (and their bottom lines) a great disservice.

“From the get-go, let’s be clear, if you are looking to mass manufacture plastic parts and components, then there really is only one viable option: injection moulding.

“Injection moulding is precise, extremely repeatable and can process a vast range of plastics, as well as being fast at the actual production stage. When the volumes are high enough, it is characterised by extremely low cost per part.

“Injection moulding’s Achilles Heel is its high set up costs and the long lead times to get to the production stage due to the necessity for steel tooling, which is often intricate in nature.”

John continued: “When looking at lower volume runs, traditionally, manufacturers have looked at CNC machining or vacuum casting. To avoid the need to produce costly and time-consuming tools for injection moulding, when the required run is low enough, these methods can offer an economical option but come with limitations of their own.

“Machining is a process that is restricted to relatively rigid materials; soft and flexible plastics do not machine well and produce inferior results.

“Vacuum casting works well with elastomer materials; however, the process is not conducive to producing parts with complex geometries or fine details.

“Due to these limitations, more and more manufacturers are assessing the use of 3D printing for lower volume runs as an alternative to CNC machining and vacuum casting. The reasons for this are based on the increasing sophistication of SLS 3D printing machines for industrial applications (greater accuracy and repeatability), the increasing palette of polymer materials that can be processed, and the ability to manufacture without the need for expensive mould tools.”

If manufacturers do not realistically assess the possibility of using 3D printing as an alternative production technology, manufacturers are genuinely missing an opportunity to make parts and components quickly, cost-effectively and accurately. And you don’t have to invest in the capital equipment in-house to make this move, as there are agencies that exist that have invested in numerous 3D printing machines so that you can subcontract your manufacturing to real experts in the technology. In this way, you also eliminate the necessity to learn a whole new set of manufacturing protocols.

John added: “It needs to be appreciated from the start that additive manufacturing is by no means suited to every application. To assess where the best fit is, you need to factor in all the benefits and the constraints.

“First and foremost, consider how big the proposed part is. Pricing is effectively based on size, and as a rule of thumb, the larger the part, the less viable 3D printing is for production. However, small components like jigs, fixtures, housings and fittings are perfectly suited to the process.

“Next, you need to assess the complexity of the proposed design. AM is agnostic to part complexity, where traditional production technologies are not. Again, as a general rule, the more complex the part, the higher the associated tooling or machining costs, and therefore the more viable additive manufacturing becomes.

“Finally, what sort of run volume do you have in mind? If you are looking for hundreds of thousands or millions, then injection moulding is your only option. However, if you want hundreds or multiple thousands of small parts, you are in the sweet spot for 3D printing as a production process.”

John concluded: “Understandably, today you may be confused, and in some instances disillusioned, about the role that 3D printing can really take on when looking at production scenarios.

“There is a lot of work to be done to illustrate that 3D printing is really now established as a viable and robust production technology when used for the correct applications and the sweet spot volumes where alternative processes struggle due to cost, timeliness, and versatility in terms of part complexity.

“At Plastics Live and AMPLAS, you will see what is available and you can learn how AM can be best included in your manufacturing regime.”

To exhibit at or visit this innovative and cutting edge event, click the links below:

- Click here to register to visit Plastics Live

- Click here to exhibit at Plastics Live