Plasticom Rises to UK Challenge to Produce Ventilator Parts

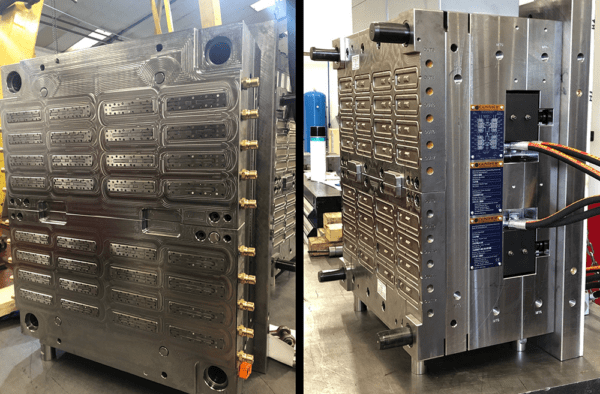

An Ashford-based injection moulding and toolmaking business this week marked the successful completion of an extraordinary order for the rapid production of thousands of parts for ventilators to be used in the battle against COVID-19.

The Plasticom Group, a family-owned business based in Ashford, Kent, has completed the final production and delivery of a 15,000-strong parts shipment to the Formula 1 racing organisation McLaren Racing Ltd.

Plasticom was invited in March to be a key player in the Ventilator Challenge UK consortium, a collective of the UK’s leading manufacturing, medical and specialist technology and manufacturing companies. The consortium includes several of this country’s Formula 1 teams such as McLaren Racing, and Plasticom was asked to help produce key components for ventilators as part of the UK government’s initiative.

The company has a long and successful track record and significant expertise in injection moulding, particularly in the medical field, from first designs to point of sale, including design, tool production, injection moulding, assembly and shipping.

Mr Edwin Simmonds, Chairman of Plasticom Group, commenting on the successful completion of this first part of the project, said: “Our fantastic team worked incredibly long hours, and under considerable pressure, to achieve delivery against what was an Immensely challenging schedule”.

“I’m so proud of the team at Plasticom for the huge efforts that they put into this mammoth task, and for helping us to deliver such large numbers of parts, in what was a very small amount of manufacturing time. We’re honoured to be part of this key national project at such a trying time, and we’re also delighted to be part of the solution,” said Mr Simmonds,

“And it was also encouraging to hear that the direct McLaren team were extremely grateful for our input, and was impressed by our unending determination and the quality of our output.”

In addition to stepping up to play its role in producing parts for ventilators in the UK Challenge, the company also has been producing a high volume of testing plates and other products that are currently being used in the NHS and international fields.

“Our close co-operation and relationship with Mitsui has allowed us to produce high quality. precision products in TPX material, from the usual small batches to high volume,” he added, “We’re now in the process of manufacturing some of the extra equipment that is required for the ventilator bellows, the base plate and canisters.”

Mrs Sonia Simmonds, Company Director, says that Plasticom’s high quality, expertise and creativity has allowed the family business to expand in recent years, not only into the medical sectors but also other key areas of the industry. “The COVID-19 crisis has shown that close cooperation among different industry sectors is possible and can play a very important role when required by the country,” she said.

Away from the Ventilator Challenge, Plasticom Group is working with UK and international organisations on joint research and development projects in the injection moulding and toolmaking industry, from inception and R&D through to the final delivery of precision products, many of which are in pioneering medical projects.

Image Caption: The team from Plasticom proudly display some of the products that the company has produced as part of the UK Ventilator Challenge. From left to right: Mr Edwin Simmonds (Chairman), Benjamin Simmonds (Business Development Manager), Ms Sharon Thorn (Assistant Production Manager), and Mrs Sonia Simmonds (Director).

The Plasticom Group

01233 621601

Website

Email