Plasticom Ramps Up Medical Production with an ENGEL All-Electric Machine

Kent-based injection moulder and toolmaker, the Plasticom Group, has upscaled its medical production as a part of the Ventilator Challenge UK, following the purchase of a new all-electric moulding machine and supporting automation from ENGEL UK.

ENGEL customer, the Plasticom Group, an injection moulder and toolmaker from Ashford in Kent, has pulled out all the stops to rapidly manufacture 15,000 vital parts which were delivered to McLaren Racing, one of several Formula 1 teams heavily involved with the ventilator consortium formed to combat COVID-19.

Plasticom has an established reputation in the field of injection moulded medical components, with expertise including design, tool production, injection moulding and assembly. The Plasticom Group has been increasingly working with UK and international organisations on joint research and development projects in the injection moulding and toolmaking industry, many of which are in pioneering medical projects.

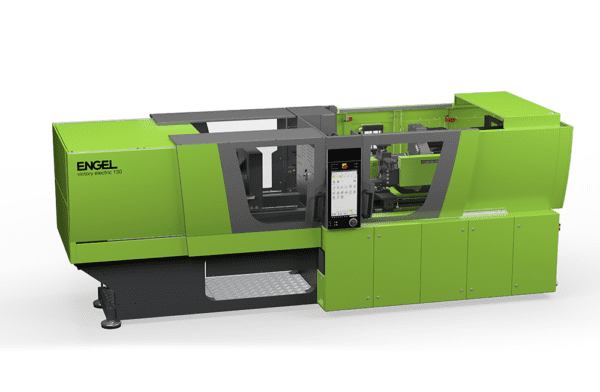

Sonia Simmonds, Director at Plasticom, explains that the recent purchase of their 4th ENGEL injection moulding machine has been in response to an increase in demand for the rapid production of specialist medical devices. The newly purchased all-electric has been paired with an ENGEL 3 axis beam robot to further increase efficiency and accuracy.

“From the delivery of the new machine, it took us a week to be up and running. During this time we moved a production tool from an existing hydraulic machine to the new one, and the ENGEL service team provided us with support in training for the all-electric technology,” says Sonia.

Nigel Baker, Managing Director, ENGEL UK adds: “We were delighted to be able to support Plasticom in their move to invest in technology to further improve the service they offer to their clients.

“ENGEL all-electric machines offer continuous repeatable performance with both high precision and volume. Many medical component manufacturers partner with ENGEL to achieve the highest level of cleanliness, precise speed, and energy savings. These are all features that a company involved in medical component moulding like Plasticom find essential.”

ENGEL

+44 (0) 1926 335000

Website

Email