Plasmatreat to Present Atmospheric-Pressure Plasma Solutions at Interplas

At Interplas, Plasmatreat UK will focus on solutions for surface treatment with plasma technology in the plastics industry. At Stand E50, visitors can get insights into plasma technology and the Plasmatreat UK team will demonstrate practically how a plasma system works.

Plasmatreat UK is a subsidiary of Plasmatreat GmbH, which is an international leader in the development and manufacture of atmospheric plasma systems for the pretreatment of substrate surfaces. Whether plastic, metal, glass or paper – the industrial use of plasma technology modifies the properties of the surface in favour of the process requirements.

Plasma technology is based on a simple physical principle: the addition of energy causes states of matter to change. If energy is added to a gas, it is ionised and enters the high-energy plasma state as the fourth state of matter. When plasma with its high energy level comes into contact with materials, the surface properties change, e.g., from hydrophobic to hydrophilic. In this way, plasma can be used to specifically change the surface of substrates in order to improve adhesion and even to join together materials that were originally incompatible.

The Plasmatreat team wants to use its participation in Birmingham to present the Openair-Plasma® technology and its various advantages to its British customers and interested people: plasma technology requires are virtually no chemicals, reduces effort, cycle times and costs, and makes long-lasting adhesive bonds possible.

For reasons of productivity, cost, and the environment, companies are increasingly abandoning the use of chemical substances or “primers” as bonding agents.

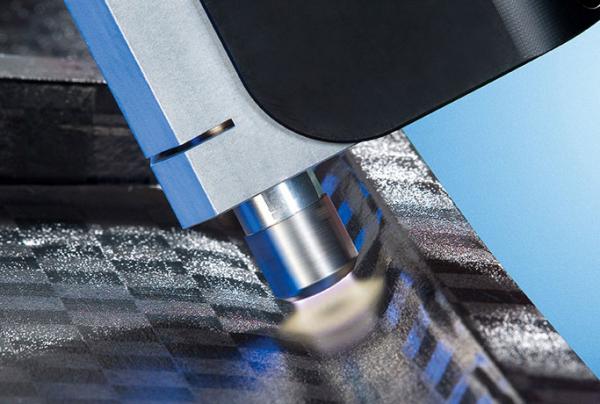

Pretreatment with Openair-Plasma® from Plasmatreat increases the adhesion and wettability of surfaces, thus enabling the use of more cost-effective material alternatives and new types of material composites while maintaining the quality of the end products.

Openair-Plasma® technology is used in automated and continuous manufacturing processes in almost every industrial sector. Examples include the automotive, electronics, transportation, packaging, consumer goods and textile industry. Still, the technology, cost and environmental advantages of plasma technology are used in medical technology and the renewable energy sector.

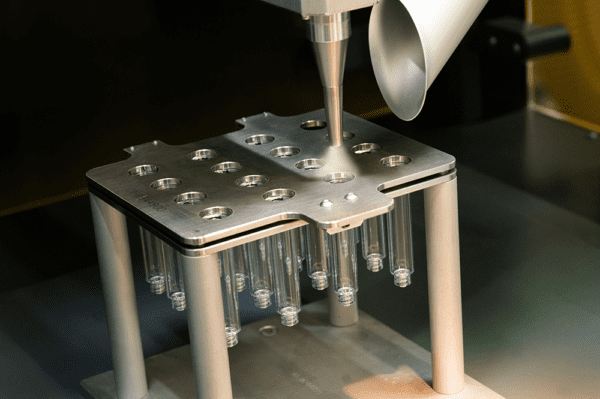

With a special demo unit, Plasmatreat will show how surface treatment with plasma works by pretreating different polymers. The plasma process is dry, non-contact, selective in location, and fast. The company’s plasma system uses a comprehensive process-control system and is fully robot-compatible and inline-capable.

For more specific requirements, functionalised coatings can be applied to the surfaces of materials using the special PlasmaPlus process. With the PlasmaPlus PT-Bond coating process, even plastics that were previously difficult to bond can be bonded directly and permanently with elastic adhesives. Primers that are harmful to the environment and health can be replaced with plasma technology.

Don’t forget to visit Plasmatreat UK on Stand E50 in Hall 4 during Interplas, which runs from 28-30 September at the National Exhibition Centre in Birmingham. In the meantime, for more information on Plasmatreat UK, visit www.plasmatreat.co.uk.

Plasmatreat

+ 44 7761 004099

Website

Email