Plasmatreat Expands Portfolio with Innovative and Sustainable HydroPlasma

|

Getting your Trinity Audio player ready...

|

Plasmatreat GmbH, the world leader in atmospheric pressure plasma technology, is expanding its portfolio with HydroPlasma – an innovative solution for the gentle, intensive and efficient removal of stubborn contaminants from plastic surfaces as well as glass and metals. This advanced technology combines the proven benefits of Openair-Plasma technology with the chemical reactivity of water, setting new standards in surface preparation for subsequent production steps.

In many high-tech industries, such as automotive, electronics, aerospace and medical, the cleanliness of surfaces is a critical success factor. Even the slightest contamination can impair adhesion in subsequent processes such as bonding, printing, painting or coating, thus jeopardising the quality and reliability of the end product. While conventional cleaning methods often rely on solvents or complex wet chemical processes, Plasmatreat offers a reliable and efficient alternative with HydroPlasma.

The innovative technology works completely without chemicals, using only compressed air, electricity and water. HydroPlasma sets new standards in industrial surface cleaning – environmentally friendly, reliable and economical.

Most importantly, HydroPlasma enhances the effectiveness of proven Openair-Plasma technology and also enables the removal of inorganic residues, such as fingerprints, that have been difficult to remove in the past. This advanced solution offers companies a highly effective and resource-efficient alternative to conventional cleaning methods.

World Innovation: HydroPlasma Reliably Removes Oil, Salt and Grease

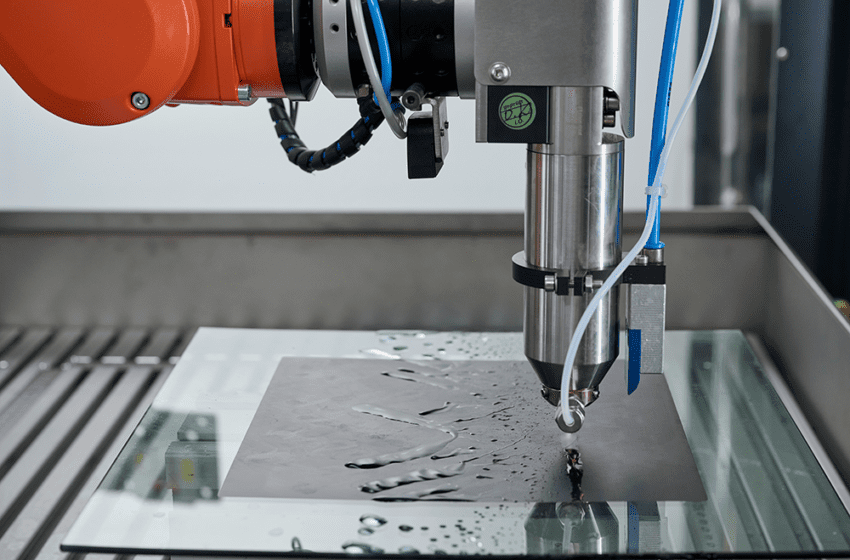

This innovative technology uses ionised water to efficiently remove even the most stubborn contaminants such as oil, salt and grease – completely chemical-free and environmentally friendly.

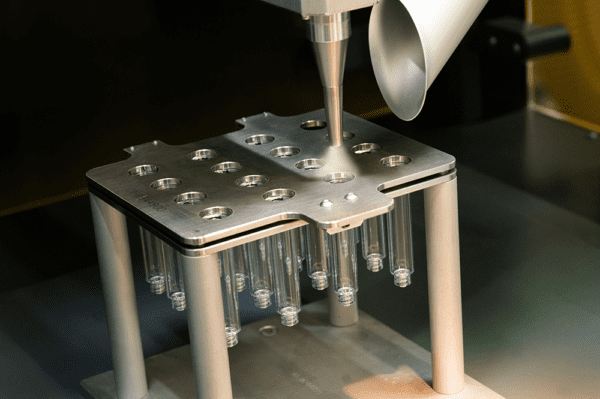

The cleaning process is based on the direct injection of water into the plasma jet, where it is ionised and converted into a highly reactive jet. A specially designed nozzle directs the jet onto the desired substrate surface. The ionised water molecules achieve a cleaning effect comparable to that of detergent in warm water, reliably dissolving and removing residues.

Openair-Plasma – sufficient in many cases for lighter contaminants

The Openair-Plasma process developed by Plasmatreat has been optimising industrial production processes for many years. A process gas, usually air, is ionised by a high-voltage arc. This creates a plasma jet that, through a specially adapted nozzle, micro-cleans surfaces with pinpoint accuracy, activating metal, glass and plastic surfaces. It reliably removes contaminants such as dust and organic residues. At the same time, plasma treatment increases the surface energy, making materials more wettable and creating optimal conditions for subsequent processes.

Plasma surface treatment improves industrial processes such as bonding, painting, printing, sealing and coating. In many applications, Openair-Plasma is an efficient and proven solution, especially when gentle pretreatment is sufficient. For applications where Openair-Plasma alone is not sufficient and goes beyond ultra-fine cleaning – for example, in the case of difficult-to-remove contaminants such as oils, greases or salts – HydroPlasma complements the Plasmatreat portfolio with another powerful cleaning technology.

Both are VOC-free, sustainable cleaning processes that do not use environmentally harmful chemicals. As a result, they not only contribute to workplace safety but also help companies reduce their carbon footprint and promote sustainable production processes.

Versatile industrial applications

HydroPlasma is particularly suitable for industries with high purity requirements and can be integrated into existing production processes as well as into existing Plasmatreat plasma systems. The process is extremely flexible and can be used for industrial processes such as battery production or applications in the electronics industry. Originally developed for metal and glass cleaning, HydroPlasma also demonstrates its advantages in the plastics sector. The cooling effect of the water supply minimises the risk of thermal damage to sensitive surfaces, allowing for gentle but effective cleaning.

HydroPlasma’s chemical-free and sustainable mode of action makes it ideal for industries such as automotive, medical and aerospace, where the highest standards of cleanliness are required. Companies benefit from improved process reliability, optimised surface quality and an environmentally friendly alternative to conventional cleaning methods.

For more information, visit: www.plasmatreat.com

Read more news from Plasmatreat here.

Plasmatreat

07725 905768

Website

Email