PCE Group Invest in Additive Manufacturing Technology

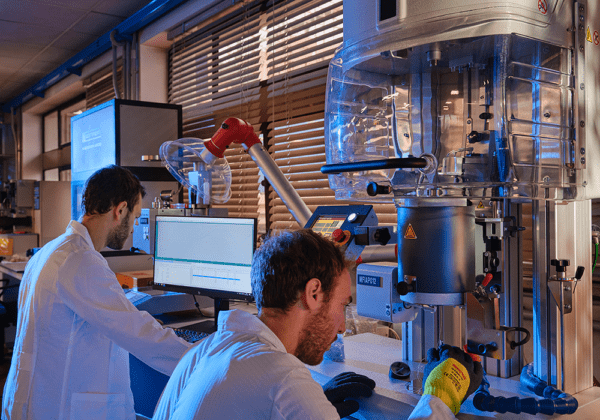

The PCE GROUP have made an investment in Additive Manufacturing Technology, complementing its range of in-house capabilities; having taken delivery of a state-of-the-art, Arburg FreeFormer 300-3X.

The Arburg FreeFormer takes pride of place in PCE’s cleanroom manufacturing facility and represents an exciting investment in the same year as the company has made a significant investment in a new machining centre.

Additive manufacturing, commonly known as 3D printing, is a rapidly growing area of manufacturing, offering some distinct advantages:

- Efficient production of intricate components

- High levels of detail and quality

- Cost and material effectiveness

- Creativity and customisation possibilities

- Limitless shapes and geometry

- Flexible material development

- Rapid turnaround times

The PCE GROUP are delighted to continue investing into emerging technologies and hope that its new additive manufacturing facilities will become a vital weapon in its arsenal, as they continue to grow within the pharmaceutical, ocular and medical sectors.

PCE GROUP Managing Director, James Cook, commented: “We have made tremendous strides in growing our market share within medical, ocular and pharmaceutical sectors, underpinned by our specialisms and in house capabilities. We look forward to unleashing the power of replicative technologies, as our automation becomes more intricate and bespoke in nature. This will undoubtedly have a positive effect on project lead times and contribute toward greater degrees of accuracy and quality, for which PCE is renowned.”

Click here to read the original article on the PCE Automation website, or visit the PCE News Archive here.

PCE GROUP

+44 (0) 1502 713287

Website

Email