Wittmann Group and NanoVoxel’s Break-Through in Micro-Manufacturing

|

Getting your Trinity Audio player ready...

|

Through the combination of the high precision 2PP µ-3D printing and the performance of the Micropower 15t micro injection moulding machine from WITTMANN BATTENFELD, NanoVoxel has successfully reduced the fabrication timeline of high-precision micro-parts to two weeks. Integration of these micro-manufacturing methods allows for swift prototyping and opens new possibilities in engineering and design across industries.

With initial applications in biomedical and consumer electronics, the breakthrough includes the production of intricate microparts with unprecedented accuracy and design freedom. NanoVoxel, based in Austria, has innovated this approach that marks a significant advancement in the landscape of efficient and customised micromanufacturing.

High-precision microparts are finding increasing relevance in different sectors including biomedical, consumer electronics, and many others. Most of the applications being developed require designs that require high precision, fast iterations, and challenge conventional design freedom.

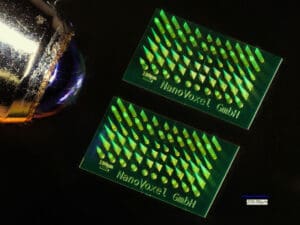

For example, current manufacturing methods such as CNC, EDM, mask-lithography, and SLA 3D printing struggle to quickly or precisely produce parts like micro-diffusers for acoustic applications featuring 70 µm 3D details (see picture 1); micro-lenses with a roughness below 10 nm; micro-needles with 5 µm tips; micro-nozzles with apertures under 20 µm; and micro-fluidic chips with specialized filters.

However, this is made possible when two advanced technologies in micromanufacturing are combined: 2PP µ-3D printing and micro-injection moulding. This expertise is NanoVoxel´s forte, a start-up founded in Vienna in 2022 to disrupt the industry standard of such micro-components.

About two decades ago, machine manufacturers, including WITTMANN BATTENFELD with its MicroPower 15 t, pioneered specialised injection moulding systems. These systems were tailored for precision micro-scale parts, offering industrial modularity and significant economic benefits. Despite this versatility and precision, the bottleneck in micro-part production persisted by their injection cavities, resulting in prolonged lead times of up to 20 weeks. Clients reluctantly accept larger tolerances (± 30 µm), but there’s a growing need for shorter lead times, and smaller features, especially in prototype development. The time-consuming precision mould production lingers as the chief bottleneck.

The breakthrough in precision combined with economic efficiency has been achieved in recent years with the 2-photon printer of UpNano, a start-up also based in Vienna and a partner of NanoVoxel. This printer is based on the principle of non-linear absorption of photons, called two-photon polymerisation (2PP). A femtosecond laser emits a narrowly focused beam to excite a photosensitive resin.

The scanner unit moves the laser beam via Galvano mirrors and lens systems to cure the resin. Like SLA/DLP 3D printing; when the light is absorbed, it triggers a chemical reaction in the resin, causing it to polymerise and solidify at the focal point of the laser beam. However, in a deviation from established 3D printing technologies, 2PP achieves full control of z-dimension polymerisation, so holes and cavities are precise and round.

The 2PP printing process offers unparalleled precision and resolution to most other manufacturing techniques, enabling the creation of complex 3D micro-structures with sub-micron accuracy, even down to the nanometer range. This makes it ideal for applications requiring particularly intricate detail with high surface quality. A variety of photosensitive resins are available for 2PP printing, including photopolymers and hybrid materials. These materials can be tailored to specific applications and offer a wide range of mechanical, optical, and chemical properties.

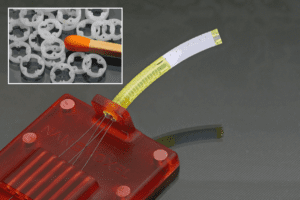

Using 2PP printers, micro parts can be printed within hours from a 3D-CAD file with a precision that cannot be achieved by conventional toolmakers, even with the most advanced machinery. Tolerances below 1 µm, structures down to 200 nm, and surface finishes with an average surface roughness better than 10 nm can be produced quickly and economically with this advanced additive manufacturing. Geometries that cannot be produced through injection moulding, due to undercuts, for example, can be produced quickly with 3D printing. Picture 2 shows an example of 2PP printed microneedle prototypes, emphasising sharp edges and micro-hollow structures.

Provisionally, the disadvantage of this technique is its capacity for high-volume production, making it uneconomical for parts larger than a few mm.

The limitations of both micro-moulding and micro 3D printing pose the question: What changes can expedite lead times, keep high precision, and still maintain high productivity?

To answer this question NanoVoxel GmbH combines the best of both worlds, establishing the union of 2PP printing with micro-injection moulding as its core business. By using 2PP 3D printing to quickly produce a high-precision mould for the micro-injection, it replicates the precision and the resolution of 2PP in moulded micro-parts with the highest efficiency. Picture 3 shows an example of a micro-gear moulded from one of these printed cavities.

NanoVoxel aims to become a one-stop service platform offering flexible and multiple manufacturing solutions and strives to become one of the most innovative companies in the micro-manufacturing world. NanoVoxel’s multi-disciplinary team of experts combine these different technologies to offer prototypes through to high-volume production as a service provider. This remarkable accomplishment compresses the timeline for structure fabrication into an incredible two-week span.

NanoVoxel has since achieved a breakthrough in the moulding of micro-parts that was previously impossible to fulfil, enabling the moulding of small, detailed structures with high accuracy and repeatability within tolerances of a few microns. In addition, high-precision 2PP 3D printing to create mould cavities enables larger parts with single-digit micron features, which would otherwise be time-consuming, expensive, or impossible to produce.

An example of NanoVoxel’s service is the development and manufacturing of an endoscope for the aiEndoscope company (Picture 4): the segments of the endoscope have been initially printed in different design variations at the prototyping stage for geometrical tests and optimisation. Upon design validation from the customer, the quickly moulded parts were produced and enabled functional and mechanical testing. All the manufacturing processes and iterations on this project were completed within 5 weeks.

The capabilities of combining different processes including mastering, casting, and sintering, allow NanoVoxel to create moulds with the highest precision, not only from 3D printing materials but also with more robust materials like glass, ceramics, and metals.

To leverage the highest precision of the moulds, NanoVoxel uses the MicroPower 15 t (Picture 5) from WITTMANN BATTENFELD, a leading manufacturer of injection moulding machines and automation solutions. With a clamping force of 150 kN, the machines of the MicroPower series are designed for the economical production of exceedingly small and micro parts with maximum precision and repeat accuracy. A two-stage screw-piston injection unit with a shot volume of 1.2 to 6.0 cm3 injects a thermally homogeneous compound. This makes it possible to produce parts with outstanding precision, extremely stable production, and exceptionally short cycle times.

The distinctive design of the machine allows the injection plunger to nearly reach the parting line of the mould. This reduces the mass cushion to a minimum. In addition, the standard version of the machine is already ideally suited for production under clean room conditions: it is designed with an enclosed housing cell.

The housing cell offers enough space for the integration of equipment options like a rotary table, robot, material drier, and temperature control units. Robots and peripheral equipment from WITTMANN are specially adapted for this machine. All drive modules of the all-electric drive system, including all mechanical components, are encapsulated in easy-to-clean housings. The extremely well-controlled injection of thermally homogeneous thermoplastics in exceptionally small quantities is necessary for successful injection moulding of precise and quality consistent mass production of micro-parts.

The combination of 2PP printing and µ-injection moulding is not limited to only the high-precision rapid tooling process. NanoVoxel GmbH brings a significant addition to the micromanufacturing industry with its capacity to 2PP print directly on parts of different materials manufactured with other processes. This print can be made on many materials including glass, ceramics, carbon substrates, metals, and plastics. Moreover, the ability to combine varied materials for different functions offers customizability ideal for rapid prototyping, product development, and mass manufacturing.

This enables customers to imprint detailed functional features directly onto bulky and larger parts obtained from more efficient processes. Initial applications have been successfully applied in the microfluidics world, where NanoVoxel printed unmouldable features into commercial chips, using their advanced printing process only where needed.

NanoVoxel´s efficiency with the micromanufacturing process unlocks new creative avenues for designers and engineers across diverse industries and revolutionises how to approach the design and fabrication of intricate, customised, and functional micro-scale parts.

Through its commitment to advancing micromanufacturing technologies and re-imagining solutions, NanoVoxel welcomes unconventional part geometry and strives to provide a creative, efficient, and yet simple approach to manufacturing.

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275777

Website

Email