MuCell: New Screw from KraussMaffei Delivers 30% More Plasticising Performance

Physical foaming of thermoplastics (MuCell) saves money, energy and resources—and is a multifaceted technology of the future. After intensive development work, KraussMaffei is presenting the new HPS-Physical Foaming universal screw for MuCell applications with 30% higher plasticising performance.

Lightweight solutions with a smaller CO2 footprint: In the effort to conserve resources, MuCell is being used more and more frequently and is a strong growth market. By adding a physical blowing agent to the thermoplastic (usually nitrogen), it is possible to save significant material weight compared to compactly manufactured components. In addition, longer flow paths are possible for thin-walled components, and foaming results in low-warpage components.

Universal screw with versatile applications

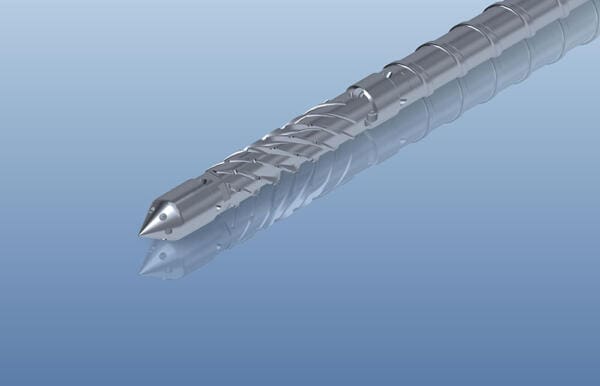

The materials used for MuCell are diverse and often contain different proportions of fibres and fillers. In the HPS-Physical Foaming, KraussMaffei has responded to this by developing a screw that can be used universally and has a 30% higher plasticising capacity. For this purpose, all screw types available on the market were compared in extensive laboratory tests. A modular concept made it possible to combine the individual components by means of bolting so that a new screw did not have to be made each time. The focus was on the mixing and gas supply area, the centre backflow barrier and the three-zone area.

More plasticising performance with less wear at the same time

The three-zone area could be enlarged without losing quality at the expense of the former and is now 17 times the diameter (previously 15D; mixing and gas supply area now 4D). This both increased the plasticising performance and had a favourable effect on the wear behaviour. Up to now, larger screws (with a correspondingly higher investment) were usually used than the component weight would normally dictate to ensure complete homogenisation of the melt before injecting the gas.

The middle non-return valve (M-RSP) closes at the end of the metering process, thereby separating the mixing and gas supply area from the three-zone section and preventing the melt from flowing back. This is the only way to keep the critical pressure above 33.9 bar and thus prevent foaming in the plasticising unit. Another task of the M-RSP is to ensure a constant shot weight. The developers’ analyses showed that the most effective design of the M-RSP has a ball check valve. Here, too, the various materials used played a major role.

Trials with different fillers

The KraussMaffei team investigated the previously existing and the newly developed screw using PP with different flow indices (MFI 11 and MFI 44), with mineral filling, with glass fibre content of 20 and 30% (LGF), and with ABS and PA6 GF 30. The plasticising performance changes depending on the compound selected and the parameters set, such as dynamic pressure.

Since KraussMaffei’s MuCell customers have a wide variety of applications worldwide, the universal screw had to reflect this diversity. The three-zone section was therefore designed with one thread (for PA6 GF30, two threads would be even better), and the M-RSP with ball check (for high-viscosity materials, a helical shear section is also possible).

The in-depth research effort yielded additional benefits beyond HPS-Physical Foaming. KraussMaffei now has a knowledge toolbox that makes it possible to develop screws specially adapted to a material—for customers who manufacture corresponding products constantly over a long period of time, for example. Here, too, the modular concept is helpful for quick tests.

Physical foam moulding is and remains a technology of the future. Driven by the desire to save money, energy and resources, it is gaining in importance all the time. The new universal screw is a milestone in this respect.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email