Moulding of PPE Begins Four Days from Design Sign-Off

With the current urgent requirement for PPE by all healthcare sectors, Plunkett Associates were approached by Resource 12 regarding the production of single-use visors, to upscale the current 3D-printing operation.

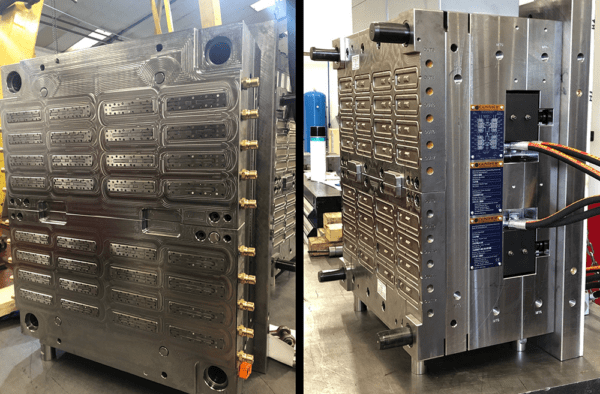

Plunkett Associates was tasked with adapting the design to make it suitable for injection moulding, with the aim of manufacturing two aluminium single cavity tools and a full production twin cavity steel tool.

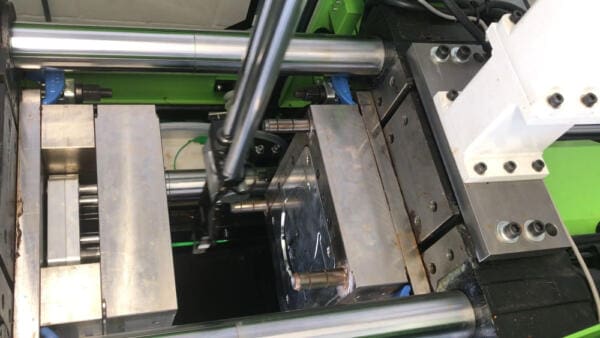

Prototypes were made to check form and fit, and a single cavity tool was trialled to test the material and mould. Four days from design sign off and Plunkett are running at 3,000 parts a day with a view to producing over 70,000 parts a week once the subsequent tools are operational.

Plunkett is delighted to say the project is proving to be a huge success, with moulding well able to support the capacity for high volume production.

Plunkett Associates would also like to thank Resource 12 for their commitment and for providing much-needed support to our health professionals at this time.

Plunkett Associates

+44 (0)1452 386608

Website

Email