Moulder Denroy Group Responds to Medical Face Mask Needs

In the grip of the pandemic in 2020, Health and Social Care Northern Ireland (HSCNI) confronted a critical shortage of personal protective equipment (PPE), especially medical-grade face masks.

To relieve pressure on the country’s medical service, Northern Ireland’s Health Minister Robin Swann wondered if regional manufacturers could fill the supply gap. Denroy Group, a major plastics injection moulder in Bangor, Northern Ireland, responded to HSCNI’s request. After demonstrating an initial medical-grade face-mask design and gathering feedback from medical professionals in late 2020, HSCNI approved Denroy’s design and issued an initial £19.5 million contract for 1 million masks. The contract was conditioned on Denroy’s ability to certify the masks to BSI and Conformité Européenne (CE) requirements and deliver from a new production facility by summer 2021.

Rapidly evolving product design

Medical personnel treating COVID-19 patients require medical-grade face masks with leak-resistant face seals and highly effective filtration of airborne droplets and particles. CE standards define two types: FFP2 face masks (aka respirators) provide a minimum of 94% particle/droplet filtration with a maximum outside air leakage of 8% (comparable to U.S. National Institute for Occupational Safety and Health [NIOSH] N95 masks), while FFP3 masks provide a minimum of 99% particle filtration and maximum leakage of just 2%.

“To attain BSI and CE approval, the mask must pass strict testing criteria on filtration, breathability and internal CO2 levels,” explains Denroy’s CEO Kevin McNamee, adding that it must also provide comfort, visibility and be easy to fit. He credits medical and clinical experts, plus HSCNI procurement experts, for the “invaluable” advice that helped Denroy finalize the Denpro™ FFP3 medical face mask design. Instead of the typical FFP3 masks that rely on a heat-formed shell made of filter material, the Denpro mask is built around a lightweight, injection-moulded frame that holds four adjustable elastic straps. A soft filter “cup” made of four nonwoven fabric layers is bonded onto one side of the frame, while a comfortable, face-hugging thermoplastic elastomer (TPE) foam seal is bonded to the other. The combination gives the Denpro mask a great fit, all-day wearer comfort and high-performance filtration.

Manufacturing challenges

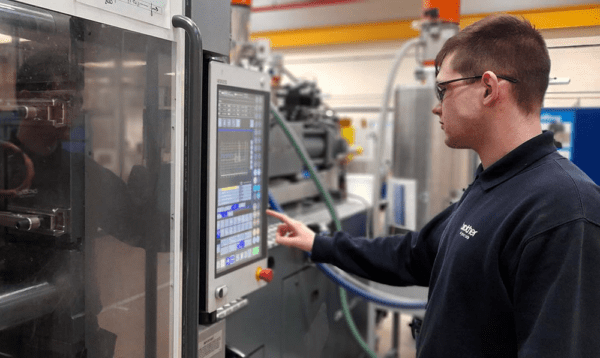

The COVID-19 emergency weighed heavily on the product development and production teams. “We literally started with a blank screen in terms of production process design, machinery specification and factory layout,” McNamee says, adding that production required employees to master a new technology — ultrasonic plastic welding — then rely on it for rapid, automated assembly of diverse plastics, including nonwoven filtration materials, into completed medical-grade masks. For help, Denroy turned to HTE Engineering Services (Dunboyne, Ireland), a maker of automated assembly systems that utilize plastic welding and, since 2018, an Emerson subsidiary. “Denroy came to us with a prototype mask design — a filter attached to an injection-moulded frame with an elastomeric face seal. They asked us to help develop automated processes and tooling for assembling these parts into finished masks using ultrasonic welding,” says Patrick Wood, HTE managing director. “In daily meetings over a period of weeks, and through a series of iterations from Denroy, we kept developing and evaluating weld solutions, weld tooling and equipment configurations as the design and materials evolved.”

Ultrasonic Welding

The frame-based mask design offered excellent filtration and breathability, with its cup shape providing a large surface area of nonwoven filtering material. But production designers had to decide how to form the filtering material into a cup shape, how many welds would be required to bond the filter materials together, and whether the welds would hold the filter to the frame. Similarly, the use of moulded TPE foam for the face seal, essential to wearer fit and comfort, required intensive weld programming and tooling development work to create an ultrasonic weld that would repeatably bond this soft part to the contours of the mask’s plastic frame. Low-volume mask production began with a manual welding process using multiple Branson 2000TM Xc ultrasonic welding systems from Emerson. After further optimisation, production accelerated with the completion of four second-generation assembly machines, each of which produces masks using four integrated Branson 2000 Xc ultrasonic welding power supplies and customised weld tooling. With additional long-term mask orders expected, Wood says that HTE is working with Denroy on a third generation of production equipment that will automate part feeding into fully automated production cells.

According to McNamee, “The FFP3 medical mask development, CE approval, tooling, production equipment design and establishment of an entirely new production facility were all conducted at a rapid pace, with the product moving from concept to production in five months. The FFP3 factory, which employs 150 people, is now fully operational with an annual capacity of over 10 million Denpro masks.”

Read more from Emerson here.

Emerson

+44 148 375 8165

Website

Email