More Efficiency, Less Cost for Maxell Moulding Services

With ASACLEAN™ GL2 by VELOX Maxell Moulding Services has found the ideal purge compound.

With over 22 years of experience in manufacturing and packaging precision moulded plastic components, Maxell Moulding Services (UK) is very experienced in many aspects of polymer processing. Yet they were surprised when, in search for a new and efficient purge compound, Maxell’s technicians tested ASACLEAN™ GL2 provided by VELOX GmbH.

“The performance of ASACLEAN™ GL2 was outstanding in every aspect”, says Hugh Davies, Moulding Technician at Maxell. “It does not only clean the machine within only 15 minutes and thereby minimises the downtime, but we could also save money by using 50 percent less purging material compared to other purge compounds. Additionally we received great expert consultation and support by VELOX.”

The Request: Purging material for lowering scrap and minimising downtime

Maxell Moulding Services was looking for a highly effective purge compound in order to have their production run as lean as possible in between colour or material changes. As Maxell offers plastic moulding services for most exacting applications in the medical, food and especially the automotive and electrical industry, the company also has high demands when it comes to purging.

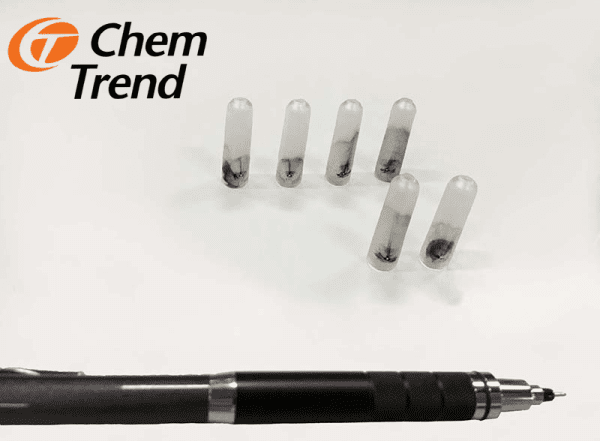

Following the trials of several purging agents from different suppliers, Maxell came to the conclusion that ASACLEAN™ GL2 serves their purpose best. After having emptied the screw and barrel from a run of 30 % glass filled black ABS, Maxell used only 8 kg of Asaclean™ GL2 before going on to a white polystyrene (PS) on a 80 mm diameter screw. No black streaks or spots were left to be seen in the PS producing an excellent result.

“With our previous purging compound we were purging for 3 to 4 hours until, finally, clean material came out of the machine”, says Hugh Davies. “This was too long, too expensive and too inefficient for us. Then we tried the Asaclean™ GL2. All it took us was 8 kg instead of 16 kg and, after only 15 minutes of purging, the machine was clean. No screw needed to be pulled and we were ready to start the next production run right after.”

The Solution: A powerful and easy to use purging all-rounder

ASACLEAN™ GL2 is a purge compound best suited to clean screws and barrels and for applications as injection moulding and extrusion. Produced by Asahi Kasei Chemical Corporation, Japan, ASACLEAN™ GL2 belongs to the purge compound family Asaclean™ with 15 additional types for various special applications, such as in the high-temperature range, transparent applications and others. It combines properties of efficiency as well as high purging power. Moreover, it is neither abrasive nor corrosive and is an all-rounder grade appropriate 2

for hard cleaning, especially during colour changes, material changes to standard polymers, sealing and hot runner cleaning. ASACLEAN™ GL2 works within a temperature range of 180°C to 330°C – if necessary, up to 360 ° C, if an exhausting system is available.

VELOX GmbH (www.velox.com) has been the exclusive pan-European distributor for Asaclean™ since 1995. The company offers 16 different grades which target specific challenges in all aspects of purging from injection and blow moulding to masterbatch and compound extrusion. “Asaclean™ is a ‘ready to use’ granulate solution that does not require mixing or predrying and no temperature adjustment on the machine”, says Enno Stapel, Product Manager at VELOX and responsible for Asaclean™. Likewise, each single granulate is cleaning-active, “there is power in every pellet”, explains Stapel.

In the global purging compound market, VELOX GmbH and its partner Asahi Kasei Corporation are among the top four companies, according to a recent study by market research company Transparency Market Research.

Benefits for plastics processors: Application specific product combined with qualified service

With the comprehensive Asaclean™ purge compound range, VELOX offers every plastics processor a targeted solution and this can be distinguished from many “compromise cleaners” which have to solve a wide range of purging challenges with a few product types. “This customised approach has proven very helpful for our customers and greatly successful for VELOX”, says Enno Stapel.

Moreover, as a solution provider, VELOX not only delivers the specific products, but also offers professional advice, assistance with selecting the right type, free samples, instructions for correct cleaning in font and film form, support for type selection, technical assistance as well as trainings on site.

“We are delighted to see that after a free consultation, combined with a trial by our local sales agent VELOX U.K. Ltd, ASACLEAN™ GL2 worked out as well as it did for Maxell Moulding Services. This is another success of the ASACLEAN ™ family as a problem solver for our customers.We look forward to a long lasting business relationship”, comments Stapel.

VELOX

+44 (0) 1442 825455

Website

Email