Moldex3D Partners with Wittmann Battenfeld

CoreTech System (Moldex3D) and Wittmann Battenfeld announce their partnership on new innovations in liquid silicone rubber injection moulding and accelerating the path to smart design and manufacturing.

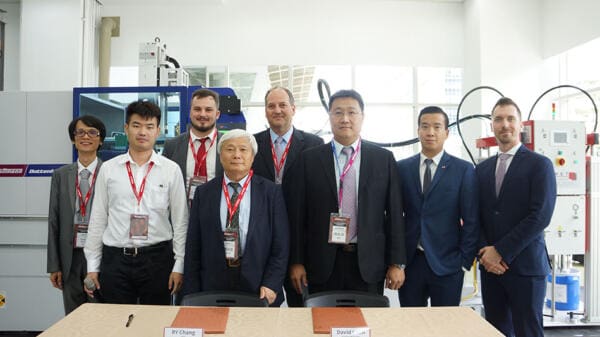

CoreTech System Co., Ltd. (Moldex3D), the leading provider of engineering simulation solutions for the plastics industry, announced that it had signed a Memorandum of Understanding (MoU) with Wittmann Battenfeld, a leading global manufacturer and supplier of plastics processing equipment on July 5, to collaborate on innovations in liquid silicone rubber (LSR) injection moulding and accelerating the path to smart design and manufacturing. The MoU was signed on behalf of Moldex3D by Dr Rong-Yeu Chang, CEO and on behalf of Wittmann Battenfeld by Mr David Chen, President of Wittmann Battenfeld Taiwan.

The MoU is aimed at bringing together both parties’ extensive knowledge and technical expertise to advance the role of simulation in LSR injection moulding. As part of the partnership, Moldex3D has acquired state-of-the-art LSR injection moulding equipment, including SmartPower 90/350 UNILOG B8 from Wittmann Battenfeld and LSR Dosing System from ELMET. By applying Moldex3D simulations, engineers will obtain new insights into the LSR cold runner, mould design and process dynamics to improve part quality and reduce cycle time. Through this innovative partnership, Moldex3D and Wittmann Battenfeld will enable manufacturers to more seamlessly integrate virtual and real worlds, transforming production performance and productivity.

“We are very excited to expand our cooperation with Moldex3D in special moulding processes, especially LSR moulding. Furthermore, the integration of mould filling simulation and machine characterisation is fully aligned with our vision of digitalising the physical manufacturing world, enabling manufacturing companies to work smarter and better based on digital simulations.”, said Mr Wolfgang Roth, Manager Applications Engineering at Wittmann Battenfeld. “The MoU with Wittmann Battenfeld represents an important milestone toward smart design and manufacturing,” said Dr Rong-Yeu Chang, CEO, Moldex3D. “By leveraging on each other’s strengths and capabilities, together, Moldex3D and Wittmann Battenfeld will create a total solution for our mutual customers to ensure the success of injection moulding.”

About Wittmann Battenfeld

Wittmann Battenfeld is a leading global manufacturer and supplier of plastics processing equipment with award-winning performance and support. Their ONE STOP SHOP offering includes a complete range of innovative robot automation and injection moulding machine technology, along with auxiliary equipment for material conveying, blending, drying, granulating, heating and cooling, for individual work cells to fully integrated system solutions.

About CoreTech System (Moldex3D)

CoreTech System Co., Ltd. (Moldex3D) has been providing the professional CAE analysis solution “Moldex” series for the plastic injection moulding industry since 1995, and the current product “Moldex3D” is marketed worldwide. Committed to providing advanced technologies and solutions to meet industrial demands, CoreTech System has extended its sales and service network to provide local, immediate, and professional service. CoreTech System presents innovative technology, which helps customers troubleshoot from product design to development, optimise design patterns, shorten time-to-market, and maximise product return on investment (ROI). More information can be found at www.moldex3d.com.

Wittmann Battenfeld

+44 (0)1933 275777

Website

Email