Micro Mould Manufacture for the Medical Industry: Enabling Breakthroughs in Complex Medical Devices

|

Getting your Trinity Audio player ready...

|

With the fast growth in the micro medical market in recent years, the demand for high-performance micro moulds has also increased significantly to meet these global higher demands for micro medical components.

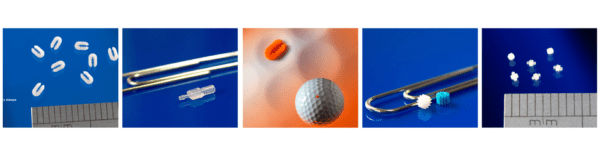

Micro injection moulding is a challenging process that requires extreme precision in dimensional accuracy and tolerance, surface finish, mechanical properties and other crucial factors. With the right manufacturers, micro parts of weight down to a fraction of a gram, with micro features consistently reproducible to sub-micron variation are achievable. The success of any micro injection moulding project starts from the very first step – micro mould tooling. Best practices in micro mould tooling can help micromoulders reduce part failure chances and manufacturing errors while cutting overall cycle times and increasing mould life.

Ultra-precision machining for Micro Moulds

One of the main challenges in designing and manufacturing micro moulds is to accommodate for the complex interrelationship of materials, design, cavitation and tight tolerances. During the micro injection moulding process, factors like mould cooling, part cooling or shrink rates can all affect the component definition, tolerance and final surface finish. Hence, it is crucial to choose a partner with dedicated Micro Mould Tooling experience and a consistent record of achievement with proven capabilities in Micro Mould manufacturing to take on these sophisticated, challenging projects for the Medical industry.

Technological developments in ultra-precision tooling manufacture and micro moulding, combined with the expertise and experience of our mould designers and technicians, make it possible to miniaturise these medical components to achieve ever-smaller features and dimensions.

For example, at Micro Systems, the ultimate machining achievements are made possible through ultra-precision machining in Micro Milling, Grinding, Micro EDM and Wire EDM. With Micro Milling, its two KERN Pyramid Nanos, with a positional accuracy of 0.0005mm (0.00002”) and a spindle speed of 55000 RPM, make it possible to machine fully hardened steel using cutters as small as 50 microns (0.002”) in diameter. Micro Systems’ latest generation Wire EDM machines can also cut through hardened steel with a wire diameter of 30 microns (0.0013”) and a positional accuracy of 0.001mm (0.00004”). These advanced technologies, along with 20+ years of experience in designing Micro Mould Tooling, have allowed Micro Systems to achieve full 3D accuracy of +/-0.5 micron in steel and maintain sub-micron level 3D accuracy on subsequent moulded components. Surface finishes of <10 Nm Ra can also be achieved directly from our machines for optical chambers completely integrated within the part.

In addition, for medical applications, Micro Mould Tooling also needs to meet strict standards to avoid defects and variance in the final medical micro injection moulded components. Micro mould manufacturing steps should be carried out in clean environments, using high-grade materials under validated processes with strict in-process quality control.

At Micro Systems, besides clean mould manufacturing environment, there is also an in-house micro moulding Class 7 cleanroom facility with 6x specialist Wittmann Battenfeld MicroPower 15 dedicated micro moulding machines, set up to run factory acceptance testing (FAT), design of experiments (DOE) process optimisation and production moulding to suit customers’ specific micro moulded medical component requirements.

Micro Mould Tooling breakthroughs in Medical Industry

With Micro Injection Moulding, medical manufacturers can now unlock new opportunities in the sector, introducing medical components of smaller and smaller scales, further strengthening medical professionals’ capabilities globally. The ability to add more functions and/or enable further form-factor reductions is largely dependent on miniaturisation, resulting in improved patient care overall, less-invasive surgeries, quicker recoveries, or better diagnostics.

One of the major breakthroughs in medical moulding is Microfluidic devices, some of which incorporate features and fluidic channels of tiny sizes. Pharmaceuticals, drug discovery, point-of-care (POC) diagnostics, next-generation sequencing, cell analysis, biomarker research, and other fields are just some examples of the potential fields of microfluidic technology. Microfluidic devices require the highest level of manufacturing precision because of the micro/nanoscale channels, surface roughness, and detection methods needed. Notwithstanding these limitations, recent developments in ultra-precision Micro Mould Tooling technology can offer the repeatability required to create microfluidic tools with the required accuracy to effectively and accurately replicate microfluidic designs into moulded plastic chips.

At Micro Systems, Microfluidic features required for the manipulation of capillary flow to generate specific capillary requirements (Filling, pinning or mixing) and microfluidic junctions required for droplet mixing and generation are precisely reproducible to within 0.0005 microns. These extremely high accuracy manufacturing processes enable Barcoded Hydrogel Beads to be mixed with cells and partitioning oil to form single-cell emulsion droplets required for Single Cell Gene Expression and Single Cell Immune Profiling Genomics. Inline filter and filter support structures within the channel structure, used to manipulate flow and cell selection within the device, are typically features of 10 to 50 microns in size. Micro Systems has developed bespoke moulding solutions to guarantee precise surface replication during moulding to ensure that the optimum feature definition is achieved.

In addition, Micro Systems’ Integrated Optics enables the continuous capillary flow required to guarantee 100% filling of inspection chambers prior to optical laser detection using Frustrated Total Internal Reflection (FTIR) to detect the presence of magnetic nanoparticles. Further extensive research of tool insert materials, processes and microfluidic manufacturing techniques allow Micro Systems ‘Integrated Optics’, traditionally machined in Nickel inserts, to be machined in hardened stainless steel (50Rc) to support high volume component moulding requirements.

Other medical devices that benefit from the revolution of Micro Mould Tooling include implantable devices, drug delivery devices (microneedle), minimally invasive surgery, etc.

Get more news from Micro Systems here.

Micro Systems

+44(0)1942 290 960

Website

Email