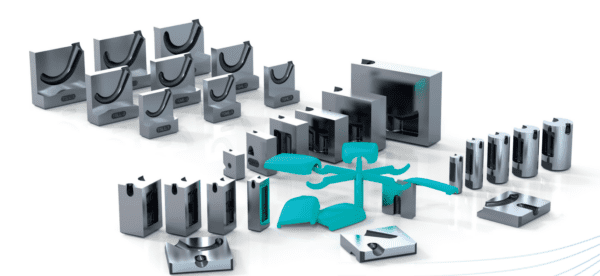

Meusburger Expands Stainless-Steel Product Range

Stainless steel components are mainly used in processing corrosive plastics or in clean room technology (e.g. medical or food processing applications).

Meusburger has expanded its product range especially in the temperature regulation components, ejectors, and demoulding product groups with numerous new stainless-steel components.

Stainless steel components for temperature regulation

Up until now, temperature regulation components for mould making have largely been made of brass. However, the demand for stainless steel elements has grown steadily in the past years. This is mainly due to clean room technology or the high temperature applications for technical plastics. On the one hand, it is a question of durability and service life, on the other hand, for the threaded parts it is a question of reliable tightness, which is not guaranteed for brass at high temperatures due to the different coefficients of expansion compared to steel plates. In October 2018, Meusburger expanded its existing stainless-steel range with the tried and trusted safety hose couplers, couplers with 90° hose nozzle, fittings, a fitting with extension and an expander sealing plug which are now also available in stainless steel.

E 17109 Stainless steel ejector and E 16709 Ventilation valve from stainless steel

Ejector pins made of stainless steel 1.4112 are now available especially for use in clean rooms and for the processing of aggressive plastics. The new E 16709 Ventilation valve supports the demoulding of thin-walled plastic parts and thus prevents damage to them. In addition, thanks to the 1.4112 stainless steel material it has the best properties for structuring or polishing.

Meusburger

07958 298166

Website

Email