Manufacturers Respond Quickly to Lateral Flow Device Demands

GÜNTHER Hot Runner Systems, Amies Innovation and RDMS joined forces in response to demand for lateral flow testing devices, producing eight impression tools in five weeks followed by two 32 cavity moulds in just ten weeks.

Lateral flow testing is an established technology that has been important in the ongoing fight against the Coronavirus.

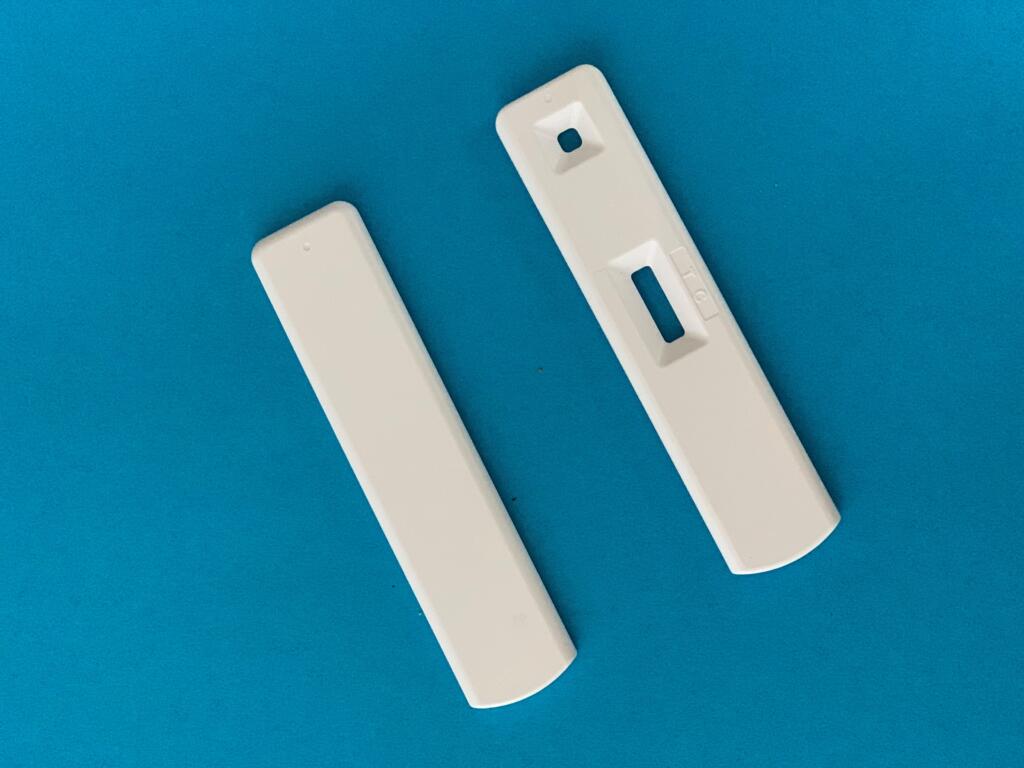

The test kit is a handheld device, with a plastic top and bottom casing enclosing a composite strip onto which various chemicals are impregnated. A blood sample mixed with a reagent is introduced through one opening and flows along the strip causing a line to appear at a specific position in a viewing window if it is a positive result, approximately 20 minutes later.

In March 2020, Amies Innovation of Chesterfield, Derbyshire were asked by an existing customer to look at the top and bottom cover parts for a Lateral Flow Device (LFD) as they were already involved in manufacturing similar components they were a natural partner for this project.

Established in 1929, Amies are a technical moulder with many years of experience in developing and manufacturing medical devices and other tightly toleranced plastic parts. The medical moulding division holds ISO 9001:2015 and ISO 13485:2016 quality management standard for medical components and assembly, as well as having the modern quality testing and measuring equipment that is critical for this kind of application.

Production requirements in the pandemic meant that initially one eight impression tool was required for the top cover and another one for the bottom, followed up by two 32 cavity moulds. Of course, the pandemic required that mouldings were able to be supplied in the shortest possible time and the challenge for Amies was then to also identify the technically capable toolmaker and hot runner supplier with whom to work to achieve these goals. Due to the importance of these parts to the fight against Covid-19 Amies, the toolmaker RDMS from Oldham and GÜNTHER Hot Runner Systems worked together to ensure that the eight impression tools, including a full valve gate hot runner, were delivered in just five weeks and even the completed 32 cavity moulds in an impressive 10 weeks.

Simon Stewart-Smith, Technical Director of Amies, said:

“Having worked with RDMS closely over the years on a number of technically demanding projects, there was no doubt they would be the correct partner for this project, with the ability to produce high-quality tooling in a very challenging lead-time. Similarly, having worked with GÜNTHER on other high specification medical and automotive projects in the past, I knew their valve gate technology was the right one for our project. Knowing the importance of the project in the context of Covid-19, although already very busy, both companies pulled out all the stops to achieve very difficult lead-times for which I can only commend them.

“In the background to all of this, Amies also needed an additional new press to support the manufacturing volumes. Our long-term trusted machinery partner Arburg, who supply all Amies injection moulding machines, were able to provide exactly what we needed to meet the project timelines.

“To complete the picture we also needed some high quality cooled conveyors with integrated box handling automation which UPM Conveyors again stepped up and provided in the required timeline to a high-quality standard.”

Chosen toolmaker Manchester-based RDMS had developed similar tooling in the past where push-fits were also critical and were, therefore, able to take a clinical approach to obtain first-time parts. They are able to take CAD data for the new part along with similar existing parts already produced by Amies and verify CAD vs part with high accuracy guaranteeing they would match each other to give the required push-fit.

RDMS uses an unmanned running system to keep competitive, which, combined with their choice of machines and automation, enables them to machine and spark erode to very high accuracy. The use of their three CMM machines verifies the tooling surfaces for quality and dimensions which helped with the fast lead times required for these tools.

Neil Richardson, Director of RDMS, said:

“Our customer Amies wanted to hit the ground running for obvious reasons and so choosing a hot runner company that would respond quickly and who offer committed technical support to feeding these parts was important and GÜNTHER was chosen. Designing and manufacturing the eight impression tools in five weeks followed by two 32 cavity moulds in just 10 weeks was very demanding and we were very proud to be part of this successful project.”

Valve gate systems from leading German hot-runner manufacturer GÜNTHER were chosen for this project based partly on successful medical projects undertaken between GÜNTHER and Amies in the past and its extensive experience in the supply of systems for medical device production worldwide. Requirements of the hot runner system were particularly for clean gate vestiges, cavity balance across all parts and reliability.

All GÜNTHER nozzles feature patented bi-metallic titanium shafts which ensure a very homogenous temperature profile across the whole length of the nozzle meaning the material is delivered to the cavity in its best possible condition. Standard nozzle type 6NMT were used with the heads machined to achieve the required small pitch centres. GÜNTHER valve gate systems also feature unique PM insert technology, essentially a replaceable needle guide and gate insert. Tolerances on these are extremely tight which, in combination with the homogenous temperature profile, gives the moulder the required high-quality gates. Another big benefit of the PM inserts is that costly reworking of gates over time is avoided as they can be easily exchanged without stripping the whole hot runner.

Manifolds are fully balanced and activation is via a single lifting plate to ensure all valve pins open and close at the same time. Via small access holes in the back valve pins with the GÜNTHER system can be simply exchanged without even taking the backplate off.

Deliveries of these systems were brought forward because of the importance of tackling Covid-19 and the eight drop systems took just four weeks and even the two 32 cavity hot runners were delivered in just five weeks. The tight delivery schedules meant that a hot half option was not considered and the systems were all installed, wired and tested by the engineer of GÜNTHER UK at RDMS.

Reiner Heendeniya, Sales Director of GÜNTHER UK, added:

“We are all trying to help in the fight against Covid-19 and there is no denying that the technical solution and delivery, including design, was a challenge but it was one we rose to and it was a real achievement to be moulding full production parts in high volumes in such a short space of time.”

GÜNTHER UK Limited

01474 879774

Website

Email